Programmable Logic Controllers (PLCs) are the control center behind modern manufacturing, ensuring machines work in perfect sync, minimizing errors, and keeping production lines running smoothly. From reducing costly downtime to optimizing every stage of the process, PLCs have made operations smarter, faster, and more reliable.

The global market for programmable logic controllers was valued at approximately USD 12.52 billion in 2021 and is projected to reach USD 22.17 billion by 2030, reflecting a compound annual growth rate (CAGR) of 6%. This growth shows the increasing reliance on PLCs for streamlining manufacturing, improving process control, and enhancing system reliability.

In this blog, we will discuss PLCs’ functionality, significant advantages, and role in industrial automation.

What Is a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is an industrial-grade computing device that automates and controls machinery, manufacturing processes, and power systems. It operates by receiving input signals from sensors, processing the data using programmed logic, and generating output signals to control actuators such as motors, valves, and alarms.

A Programmable Logic Controller (PLC) collects information from sensors before applying programmed rules to the data and activating control devices, including motors, valves, and alarms, through output signals.

The manufacturing industry adopted Programmable Logic Controllers (PLCs) during the 1960s to address complex relay control systems through improved flexibility and reliability and simpler programming methods. The solid-state construction of PLCs enables durability in an industrial environment, unlike conventional relay logic systems.

PLCs operate through three main functions:

- Input monitoring: Inputs can be digital (on/off) or analog (continuous values like temperature or pressure)

- Logic processing: The central processing unit (CPU) executes the logic program, making real-time decisions

- Output control: Outputs then activate control elements based on the programmed logic.

PLCs are widely used due to their reliability, efficiency, and ease of programming using languages like Ladder Logic and Structured Text. They are also highly adaptable, allowing integration with SCADA and IoT systems for advanced industrial automation. Their modular design enables scalability, making PLCs essential for modern industry automation.

Different Types of PLC

The primary categories of PLC include:

-

Fixed PLCs

Also known as compact or integrated PLCs, these units have a predetermined number of input/output (I/O) points built into a single module. They are cost-effective and ideal for small-scale applications with straightforward control requirements. However, their fixed configuration limits expansion capabilities, making them less suitable for advancing and growing systems.

-

Modular PLCs

These PLCs consist of separate modules—such as the central processing unit (CPU), power supply, and various I/O modules—that can be assembled to form a customized system. This modularity allows for easy expansion and flexibility, enabling users to add or replace modules. Modular PLCs are well-suited for complex or large-scale applications requiring future scalability.

-

Unitary PLCs

Often called compact or integrated PLCs, unitary PLCs combine the CPU, I/O interfaces, and power supply into a single unit. They are built for basic control tasks and are easy to install and maintain. While they offer simplicity and cost advantages, unitary PLCs are limited in customization and expansion, making them best suited for simple, standalone applications.

Selecting the appropriate type of PLC depends on factors such as the application’s complexity, the need for future expansion, and budget constraints. Understanding these types helps design an efficient and scalable automation system tailored to specific industrial needs.

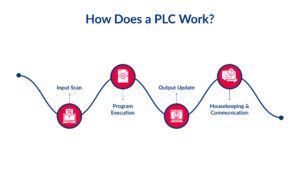

How Does a PLC Work?

A Programmable Logic Controller (PLC) operates continuously, executing steps to monitor inputs, process logic, and control outputs. This process ensures real-time automation of industrial machinery and systems.

-

Input Scan

The PLC first reads data from input devices such as sensors, switches, and encoders. These inputs can be digital (on/off states) or analog (variable values like temperature, pressure, or speed). The collected data provides real-time information about the status of the connected machinery.

-

Program Execution

Once input data is collected, the PLC executes its user-defined control program. This logic is typically written in Ladder Logic, Structured Text, or Function Block Diagrams and is stored in the PLC’s memory. The PLC makes decisions based on the programmed logic, determining the appropriate output actions.

-

Output Update

After processing the logic, the PLC sends signals to output devices such as motors, solenoids, actuators, alarms, and displays. Outputs can be digital (on/off control for devices like motors or lights) or analog (variable control for temperature adjustment or motor speed regulation).

-

Housekeeping & Communication

Before repeating the cycle, the PLC performs diagnostics and internal checks to ensure proper operation. Many modern PLCs also communicate with SCADA (Supervisory Control and Data Acquisition) or HMI (Human-Machine Interface) systems for remote monitoring and control.

This cyclic operation, known as the scanning process, occurs within milliseconds, enabling high-speed automation and real-time decision-making in industrial applications.

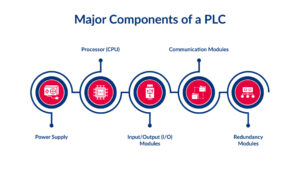

Major Components of a PLC

A Programmable Logic Controller (PLC) consists of several significant components that work together to execute automation tasks efficiently. Each component ensures smooth operation, reliability, and communication with industrial devices. Below are the essential components of a PLC:

-

Power Supply

The power supply converts incoming electrical voltage (such as 230V AC, 120V AC, or 125V DC) into a stable signal level required by the PLC processor and other modules. It ensures uninterrupted operation and prevents voltage fluctuations from affecting system performance. Some PLCs use built-in power supplies, while others require separate power modules.

-

Processor (CPU)

The processor is the brain of the PLC. It executes control logic, processes input signals, and generates output responses based on the programmed instructions. It also manages memory to store control programs and data. Advanced PLCs have high-speed processors for complex automation tasks, ensuring precise and efficient control.

-

Input/Output (I/O) Modules

I/O modules act as the interface between the PLC and field devices. Inputs receive signals from sensors, switches, and transmitters, while outputs send commands to actuators, motors, and relays. Depending on the signals they process, these modules can be digital or analog. Modular PLCs allow easy expansion of I/O capacity.

-

Communication Modules

Communication modules enable data exchange between PLCs, SCADA systems, and other industrial networks. They support protocols such as Ethernet, Modbus, Profibus, and ControlNet. Some PLCs have built-in communication capabilities, while others require separate network integration and remote monitoring modules.

-

Redundancy Modules

Redundancy ensures system reliability for critical applications. Redundant PLCs have backup processors that take over in case of failure, preventing downtime. Redundancy modules manage synchronization between primary and backup controllers, ensuring seamless switching in high-availability environments.

Advantages of Using PLCs in Industrial Automation

PLCs offer numerous benefits that make them the preferred choice for industrial automation. They simplify complex processes, improve efficiency, and ensure manufacturing and production systems reliability. Their flexibility, fast processing speed, and ease of maintenance make them essential for industries looking to enhance automation and optimize operations with minimal downtime.

-

Easy to Program

PLCs use simple programming languages like Ladder Logic, making them easy to learn and use. Engineers and technicians can quickly write and modify programs without extensive coding knowledge. Their user-friendly interface allows businesses to train staff efficiently, reducing the learning curve and making automation more accessible for various industries.

-

Highly Reliable

PLCs are solid-state devices with no moving parts, making them more durable than traditional mechanical systems. They can operate in harsh industrial environments with minimal maintenance. Their durable design ensures continuous operation, reducing the risk of system failures and increasing productivity in manufacturing plants and industrial facilities.

-

Flexible and Scalable

A single PLC can control multiple processes, allowing businesses to customize automation solutions. Companies can upgrade or expand their systems by adding more PLCs or input/output modules. This scalability makes PLCs ideal for growing industries, enabling seamless integration with new machinery and technology advancements.

-

Fast and Efficient

PLCs process instructions in milliseconds, allowing quick decision-making and real-time control. This rapid response time enhances production speed and reduces waste. Additionally, PLCs consume less power than older relay-based systems, making them an energy-efficient solution that helps companies reduce operational costs.

-

Easy Troubleshooting and Maintenance

PLCs have built-in diagnostic features that help identify problems quickly, minimizing downtime and keeping industrial processes running smoothly. Maintenance teams can monitor system performance, detect real-time errors, and make software updates without suspending production, ensuring seamless operations and improved efficiency.

Common Applications of PLCs

PLCs are crucial in modern industrial operations, from manufacturing to energy management. Below are some typical applications where PLCs make a significant impact.

-

Manufacturing and Assembly Lines

PLCs control robotic arms, conveyors, and automated machines in manufacturing plants. They help improve production speed and accuracy, ensure that machines operate in a synchronized manner, and reduce human errors. PLCs also allow quick adjustments to production settings, leading to higher efficiency and lower production costs.

-

Packaging and Material Handling

PLCs automate sorting, labeling, and packaging in warehouses and logistics centers. They ensure precise handling of goods, reducing waste and damage. Conveyor belts, barcode scanners, and robotic pickers work together using PLCs. This automation speeds up the packaging process and improves order accuracy.

-

Energy and Utilities

Power plants and water treatment facilities rely on PLCs to monitor and control operations. They regulate temperature, pressure, and flow rates in real time, helping to optimize energy usage and reduce waste. PLCs also improve system reliability by detecting faults early, preventing costly failures, and ensuring uninterrupted service.

-

Automotive Industry

PLCs play a vital role in vehicle production. They control automated welding, painting, and assembly lines. By ensuring precision in these processes, PLCs improve product quality. They also allow manufacturers to switch between different vehicle models easily. This flexibility helps the automotive industry meet market demands efficiently.

-

Food and Beverage Industry

PLCs automate food processing, mixing, and packaging. They help maintain consistent product quality and hygiene. Temperature and timing controls ensure proper cooking and sterilization. PLCs also track ingredients and ensure compliance with safety standards. This automation reduces errors and enhances production efficiency in food and beverage plants.

Choosing the Right PLC for Your Business

Selecting the right PLC is essential for efficient automation. Environmental conditions and future scalability are also necessary. Below are crucial factors to help you choose the best PLC.

-

Processing Power and Memory

A PLC’s processing power determines how quickly it can execute tasks. For complex operations, choose a PLC with a fast CPU. Memory storage is also essential for storing programs and data. If your system requires handling multiple tasks, ensure the PLC has enough memory to avoid slow performance or crashes.

-

I/O Requirements

The number and type of inputs and outputs (I/O) affect a PLC’s compatibility with your system. Some processes require digital I/Os, while others need analog I/Os. Carefully assess your automation needs. Ensure the PLC has enough I/O ports and supports future expansion to accommodate new devices or sensors.

-

Communication Capabilities

Modern industries rely on data exchange between machines. If your system needs networking with SCADA, IoT platforms, or cloud computing, choose a PLC with Ethernet, Modbus, or Profibus connectivity. Proper communication ensures seamless integration and real-time monitoring, which helps optimize performance and reduce downtime.

-

Environmental Conditions

Industrial environments can be harsh, with extreme temperatures, humidity, and vibrations. To withstand these conditions, select a PLC with a rugged design. Look for PLCs with high ingress protection (IP) ratings or NEMA-rated enclosures. This ensures reliable performance and prevents damage in demanding work environments.

-

Scalability and Expandability

Business needs to grow, and your automation system should grow with them. Choose a PLC that supports easy expansion without significant hardware changes. Modular PLCs allow adding extra I/O modules and communication interfaces. This flexibility ensures long-term usability and saves costs on future upgrades.

Transform Your Industrial Automation with LSElectric America Inc.

As industries move toward smarter and more connected automation systems, LSElectric America Inc. is at the forefront, providing advanced panel control, automation, and power distribution solutions.

From reliable PLC systems and servo motion control to advanced power distribution products like transformers and vacuum circuit breakers, we offer a comprehensive suite of solutions to enhance efficiency and streamline operations.

Our solutions include:

Optimize your industrial systems with innovative, future-ready solutions.