Nearly 9 percent of all electricity generated worldwide is lost during transmission and distribution before it ever reaches consumers. This figure, reported in global power system studies, shows the critical need for efficient equipment and robust infrastructure.

Among the most important elements ensuring this efficiency are transformers and switchgear. Transformers adjust voltage levels for long-distance transmission and safe consumption, while switchgear provides the control, isolation, and protection that keep systems secure.

Although they operate side by side with distinct roles, they function together to ensure system stability and efficiency. Understanding switchgear and transformer functions is essential for engineers, facility managers, and decision-makers who must ensure safety, reliability, and cost efficiency.

In this blog, we will discuss the differences, compare technical aspects, and explain how they work together in real-world power applications.

What Is a Transformer?

A transformer is a static electrical device that transfers electrical energy between circuits through electromagnetic induction. Its primary purpose is to step up (increase) or step down (decrease) voltage levels while keeping frequency constant.

Core Functions

- Voltage transformation for efficient transmission and safe utilization

- Isolation between primary and secondary circuits

- Power distribution in industrial, commercial, and residential systems

Types of Transformers

- Power Transformers – Used in transmission networks, typically above 33 kV.

- Distribution Transformers – Step down voltage for consumer use, usually 11 kV to 400 V.

- Instrument Transformers – Current transformers (CTs) and potential transformers (PTs) for measurement and protection.

Transformers operate silently, with no moving parts, but they play a critical role in reducing transmission losses and ensuring that electricity can travel long distances economically.

What is Switchgear?

Switchgear is a broad term that refers to the combination of electrical disconnect switches, circuit breakers, fuses, relays, and protective devices used to control, isolate, and protect power systems.

Core Functions

- Interrupting fault currents (short circuits, overloads)

- Isolating circuits for maintenance or emergencies

- Protecting transformers, generators, and other equipment

- Ensuring reliability and safety in operation

Types of Switchgear

- High Voltage (HV) Switchgear – Above 36 kV, used in transmission networks.

- Medium Voltage (MV) Switchgear – 3.3 kV to 36 kV, used in substations and large industrial setups.

- Low Voltage (LV) Switchgear – Below 1 kV, used in commercial and residential buildings.

Switchgear reacts instantly to abnormalities, isolates faults, and ensures the uninterrupted operation of healthy sections.

Comparing Switchgear and Transformers: Roles and Functions

The following comparison outlines how transformers and switchgear function together while performing distinct yet complementary roles in power systems.

| Aspect | Transformer | Switchgear |

| Primary Function | Changes voltage levels (step-up/step-down) | Controls, isolates, and protects circuits |

| Working Principle | Electromagnetic induction | Mechanical and electrical interruption |

| Role in Power System | Facilitates power transfer | Ensures safety, reliability, and fault clearance |

| Components | Core, windings, insulation, cooling system | Circuit breakers, relays, fuses, isolators, busbars |

| Location | Found in substations, generation plants, distribution systems | Installed at every node where protection/control is needed |

| Operation | Passive (no moving parts) | Active (requires mechanical operation) |

| Protection Role | Needs protection from switchgear | Provides protection to transformers and other equipment |

| Maintenance Needs | Oil checks, insulation testing, thermal monitoring | Breaker servicing, relay calibration, insulation checks |

| Failure Consequence | Blackouts, equipment damage, system instability | Arc flash hazards, inability to isolate faults |

| Integration | Works with switchgear for safe operation | Protects transformers and ensures system continuity |

1. Primary Function

The primary purpose of a transformer is to change voltage levels while maintaining the overall power nearly constant, except for minor losses due to resistance, hysteresis, and eddy currents. According to the U.S. Energy Information Administration (EIA), transmission losses account for about 5–6% of the electricity transmitted and distributed in the United States. Transformers play a key role in reducing these losses by enabling high-voltage transmission.

For example, a power transformer located at a generating station steps up the generated voltage from 11 kV or 25 kV to 220 kV, 400 kV, or higher for long-distance transmission. This step-up process reduces the current for the same power transfer, which in turn reduces transmission line losses.

At the distribution end, transformers step the voltage down to 11 kV, 6.6 kV, or 400 V for industrial, commercial, and domestic use. Without voltage transformation, the system would be inefficient and uneconomical.

Working in coordination with transformers, switchgear ensures the safe and reliable operation of the power system. It controls the flow of electricity, isolates equipment when needed, and protects the system against abnormal conditions such as short circuits, overloads, or ground faults.

By opening or closing circuits safely, switchgear minimizes the risk of damage to expensive assets such as transformers, motors, or transmission lines. It also enables maintenance by allowing safe disconnection of equipment without interrupting the entire system.

2. Working Principle

Transformers work on the principle of electromagnetic induction as defined by Faraday’s Law. When an alternating current flows through the primary winding, it generates a time-varying magnetic flux in the laminated steel core. This magnetic flux links with the secondary winding and induces an alternating voltage proportional to the turns ratio of the windings.

The relationship between primary voltage, secondary voltage, and turns ratio allows transformers to either increase or decrease voltage levels. Transformers have no moving parts, which contributes to their high reliability and long operational life.

Complementing the passive electromagnetic operation of transformers, switchgear works on electromechanical and arc-quenching principles. When a circuit breaker in the switchgear interrupts fault current, an electrical arc forms between the separating contacts. The arc must be extinguished quickly to prevent damage. Different types of arc-quenching media are used depending on the application. These include air blast, vacuum, sulfur hexafluoride (SF₆), and oil.

Modern switchgear relies heavily on vacuum and SF₆ technologies due to their efficiency and reliability. Protective relays detect abnormal conditions and send signals to operate circuit breakers, ensuring that faults are cleared in a fraction of a second.

3. Role in the Power System

Transformers:

- Convert electrical energy to higher voltage levels for long-distance transmission.

- Reduce voltage to usable levels for industrial, commercial, and residential consumers.

- Enable efficient transport of electricity across large geographic areas.

- Minimize transmission line losses during power delivery.

- Form the backbone of reliable energy delivery systems.

- Without transformers, economical long-distance transmission would not be possible.

Together, transformers and switchgear form a synchronized system where transformers handle energy transfer while switchgear ensures safe, controlled operation.

Switchgear:

- Protect the system by isolating only the faulty section during abnormal conditions.

- Maintain system stability by preventing faults from spreading.

- Ensure continuity of supply for unaffected parts of the network.

- Enhance safety by isolating energized equipment during maintenance or emergencies.

- Provide protection against cascading failures in interconnected networks.

- Modern switchgear includes automation and remote-control features for faster response and improved reliability.

4. Components

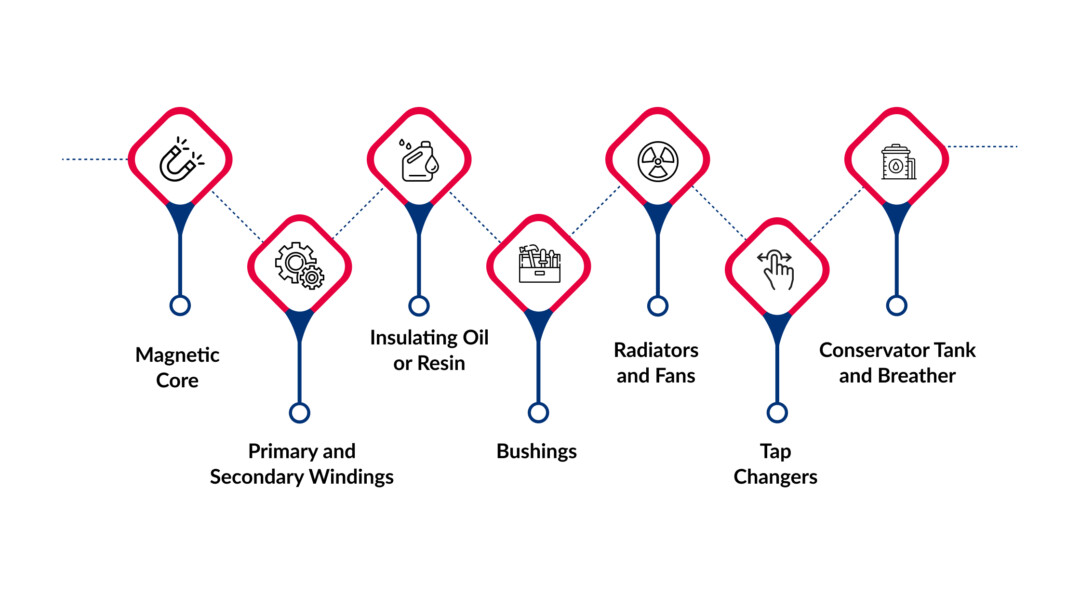

Transformer Components:

- Magnetic Core: Provides a low reluctance path for magnetic flux and minimizes losses.

- Primary and Secondary Windings: Copper or aluminum conductors wound around the core to transfer energy by induction.

- Insulating Oil or Resin: Provides dielectric strength and acts as a cooling medium in oil-immersed designs.

- Bushings: Insulated terminals that allow connection of windings to external circuits.

- Radiators and Fans: Provide cooling by dissipating heat generated during operation.

- Tap Changers: Adjust the turns ratio to regulate output voltage under varying load conditions.

- Conservator Tank and Breather: Maintain oil volume and prevent moisture ingress.

While transformers handle voltage conversion, switchgear complements them by providing control, isolation, and protection for each circuit they serve.

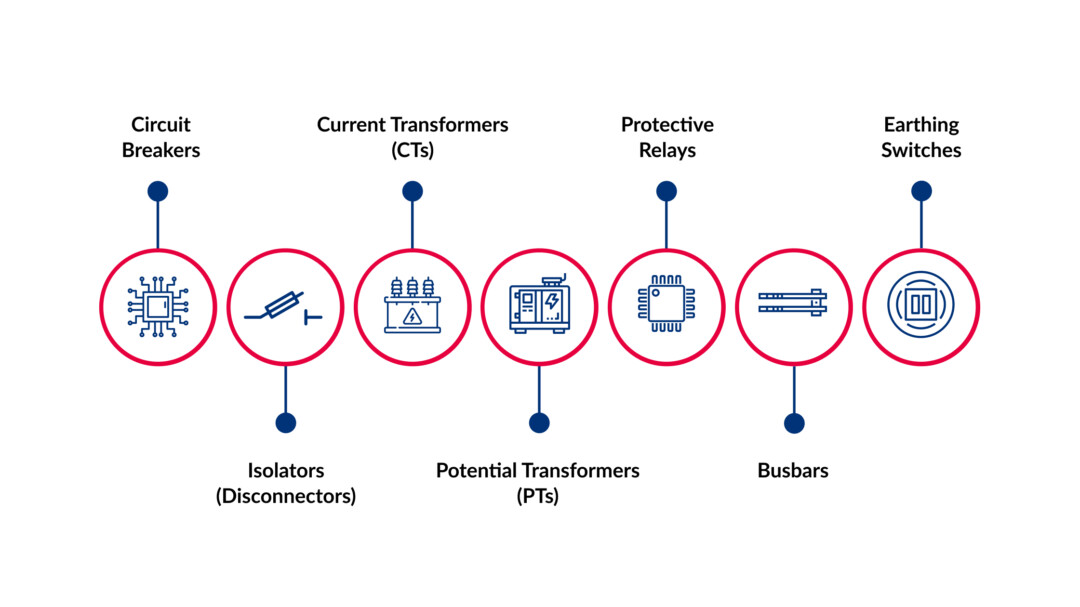

Switchgear Components:

- Circuit Breakers: Interrupt fault currents and restore safe conditions.

- Isolators (Disconnectors): Provide visible isolation for maintenance activities.

- Current Transformers (CTs): Measure current levels for metering and protection.

- Potential Transformers (PTs): Step down voltage for metering and relay protection.

- Protective Relays: Detect abnormal system conditions and initiate tripping.

- Busbars: Conductors that distribute power to multiple outgoing circuits.

- Earthing Switches: Provide grounding to discharge residual energy safely.

5. Location in the Network

Transformers are strategically placed at generation plants to step up voltage for transmission, at transmission substations to step down voltage for distribution, and at distribution substations to supply power to end users. Large industrial facilities often have dedicated transformers that supply electricity at specific voltage levels suitable for heavy machinery.

In coordination, switchgear is installed at every stage where control, isolation, or protection is required to support transformer operation and overall network reliability. At generating stations, high-voltage switchgear is used to control the output of generators. Along transmission lines, switchgear isolates faulty segments and ensures stable operation.

In distribution systems, medium and low voltage switchgear manages feeders supplying industries, commercial complexes, and residential areas. Even within buildings, switchgear is present in the form of distribution panels and breaker systems.

6. Operation Mode

Transformers are passive devices that operate continuously without requiring external signals or intervention. Once connected to a source, they adjust voltage levels automatically according to their winding ratios. Their operation depends solely on the alternating current input and the magnetic coupling between windings.

Switchgear operates actively. Circuit breakers, contactors, and relays require mechanical movement or electronic actuation to function. During normal operation, switchgear allows electricity to flow uninterrupted.

When a fault occurs, relays detect the abnormality and send a trip signal to circuit breakers, which then open mechanically to interrupt current. Modern switchgear often integrates microprocessor-based relays for faster and more accurate operation.

7. Protection Role

Transformers require protection from overcurrent, overvoltage, overheating, and internal faults such as winding short circuits. Common protective devices include differential relays, Buchholz relays, sudden pressure relays, overcurrent relays, and surge arresters. These protection schemes ensure that any developing fault within the transformer is detected early and isolated before catastrophic failure occurs.

Switchgear works alongside transformers to provide the overall protective function for power networks, shielding transformers, generators, transmission lines, and consumer loads. By coordinating with protective relays, switchgear ensures that only the affected section of the network is isolated. This minimizes disruption and prevents widespread outages. Switchgear not only protects equipment but also safeguards human operators by providing safe isolation of live circuits.

8. Maintenance Needs

Transformer Maintenance Requirements:

- Periodic testing of insulating oil to check for dielectric strength, moisture content, and dissolved gases.

- Dissolved Gas Analysis (DGA) to identify early signs of insulation breakdown or overheating.

- Insulation resistance testing and winding resistance testing.

- Inspection and servicing of load tap changers to ensure reliable voltage regulation.

- Thermal imaging to detect hot spots.

- Cleaning and inspection of bushings and connections.

Coordinated maintenance of transformers and switchgear ensures overall system reliability, as both require periodic inspection and testing suited to their respective functions.

Switchgear Maintenance Requirements:

- Regular inspection and servicing of circuit breaker contacts to prevent wear and arcing damage.

- Relay calibration and testing to maintain accuracy of protection schemes.

- Insulation resistance testing of busbars and cables.

- Functional testing of tripping mechanisms.

- Arc flash risk assessment and mitigation measures.

- Cleaning, lubrication, and mechanical inspection of moving parts.

9. Failure Consequence

Failure of a transformer can result in a complete loss of supply to a large section of the network, long outages, and costly replacement. In addition to equipment damage, it may cause instability in the grid, leading to widespread blackouts. Replacing a large power transformer can take months due to procurement and logistics.

Both components are interdependent; a transformer fault can strain connected switchgear, and vice versa, making preventive care and monitoring crucial for overall system stability. Failure of switchgear, particularly circuit breakers, can lead to dangerous arc flashes, fire hazards, and the inability to clear faults. This can cause damage to transformers, cables, and connected equipment. In severe cases, it may pose risks to human life.

Since switchgear is distributed throughout the network, its failure can affect local areas or expand into larger system instability if redundancy and protection coordination are inadequate.

10. Integration in Systems

Transformers and switchgear are integrated within substations and industrial facilities. A typical configuration involves a transformer connected to incoming and outgoing feeders protected by switchgear. At the incoming side, high-voltage switchgear isolates the transformer from the grid when required. At the outgoing side, medium or low voltage switchgear controls feeders supplying industries or consumers.

This integration ensures that transformers are not overloaded, and any faults are cleared promptly. Protection coordination between transformer relays and switchgear breakers ensures selectivity, where only the faulty section is isolated.

The integration also allows safe maintenance and testing by providing isolation points and grounding arrangements. Together, transformers and switchgear ensure efficient, reliable, and safe operation of the power system.

How Do Transformers and Switchgear Work Together?

Transformers and switchgear form the foundation of modern power infrastructure. Here’s how:

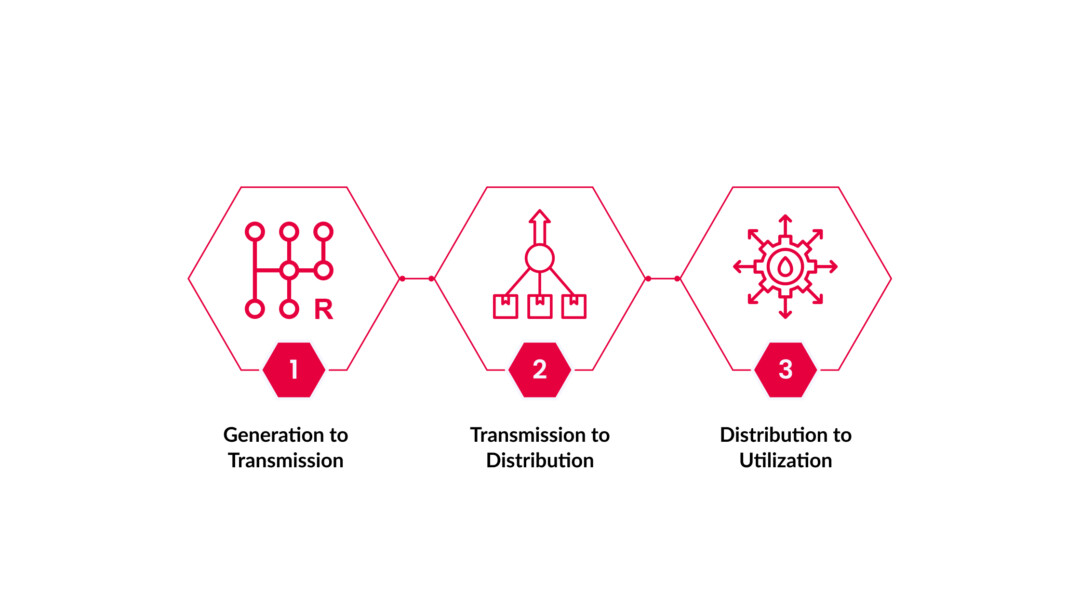

Generation to Transmission

- Power is generated at ~11–25 kV.

- Step-up transformer raises voltage to 220–765 kV for long-distance transmission.

- Switchgear ensures safe synchronization and fault protection at this stage.

Transmission to Distribution

- High-voltage power reaches substations.

- Step-down transformer lowers it to 33 kV or 11 kV.

- Switchgear controls and protects outgoing feeders.

Distribution to Utilization

- Distribution transformers reduce voltage to 415 V or 240 V.

- Low-voltage switchgear protects circuits in commercial buildings and homes.

Together, they form a continuous chain of energy transfer and protection.

Major Considerations in Integrating Transformers and Switchgear

When transformers and switchgear operate together in a power system, careful integration is essential. The following considerations highlight the technical and safety factors that must be addressed for reliable performance.

- Coordination of Protection: Relay settings must be matched with transformer impedance and fault current levels to ensure accurate operation and avoid unnecessary tripping of protective devices.

- Fault Level Calculations: The interrupting capacity of switchgear must always be greater than the maximum available fault current at the transformer’s secondary to prevent failure during fault clearance.

- Cooling and Ventilation: Transformers produce significant heat during operation, and switchgear enclosures can trap thermal energy, so effective cooling and ventilation systems must be included in the design.

- Safety and Standards: All installations must comply with IEEE, IEC, and ANSI standards, and additional safety measures such as arc flash studies, grounding systems, and proper clearances must be implemented.

- Maintenance Planning: Transformers and switchgear have different maintenance needs, and aligning their schedules ensures reliability, reduces downtime, and improves overall system performance.

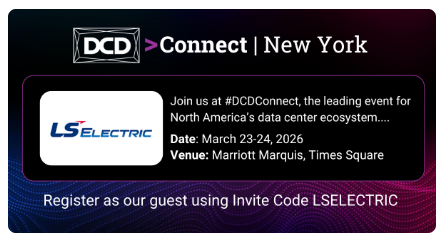

- Reliable Product Selection: The long-term safety and efficiency of any power system depend on the quality of equipment used. Selecting reliable transformers and switchgear from trusted manufacturers like LS Electric America Inc. ensures compliance with international standards, reduces the risk of premature failure, and provides greater confidence in system performance.

Build Reliable Power Networks with LS Electric America Inc.

Safe, efficient, and future-ready power systems rely on the seamless integration of transformers and switchgear. LSElectric America Inc. provides a comprehensive lineup of products that work together, simplifying system design and enhancing reliability.

- Transformers: High-performance, energy-efficient transformers engineered for industrial and commercial applications, with options for oil-filled and dry-type designs.

- Switchgear: Advanced low- and medium-voltage switchgear solutions offering comprehensive protection, arc-flash safety features, and modular expandability.

By choosing LS Electric as your partner, you gain access to seamlessly integrated equipment, proven safety standards, and lifecycle support from one source.

Build a safer, smarter power system.