Industrial automation depends on systems that can control, monitor, and optimize complex processes with precision. Two of the most widely used technologies in this field are Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC). Both are built to automate tasks and maintain process efficiency, but they differ in structure, application, and scale.

Choosing between DCS and PLC systems affects how a plant operates today and how easily it can adapt to future production goals. The right control system improves consistency, reduces downtime, and ensures better safety and quality management across operations.

The global industrial automation and control systems market is expected to reach USD 391.1 billion by 2032, growing at a CAGR of 8.4%. This growth underscores the growing reliance on automation to enhance production efficiency and ensure operational safety.

In this blog, we will discuss what DCS and PLC systems are, outline their core differences, and discuss when each is best suited for specific industrial applications.

What Is a PLC (Programmable Logic Controller)?

A Programmable Logic Controller (PLC) is a digital control device used to automate industrial processes such as manufacturing, assembly lines, or machine operations. It receives inputs from sensors or user commands, processes the information through programmed logic, and produces outputs to control actuators, motors, or other devices.

PLCs were first developed in the late 1960s to replace hard-wired relay systems, offering a more flexible and reliable solution for automation. Over time, they have become standard in discrete manufacturing, packaging, automotive production, and other industries that require high-speed, sequence-based control.

Common PLC functions include:

- Monitoring inputs: Reading data from sensors, switches, and field devices

- Processing logic: Executing user-defined programs such as ladder logic or function blocks

- Controlling outputs: Sending signals to actuators, solenoids, and motor drives

- Ensuring safety and diagnostics: Detecting faults and maintaining safe operation

Modern PLCs are compact, modular, and designed for continuous operation in harsh environments. They can handle rapid input/output cycles, integrate with Human-Machine Interfaces (HMIs), and connect to supervisory systems like SCADA for higher-level control and monitoring.

What Is a DCS (Distributed Control System)?

A Distributed Control System (DCS) is an industrial automation system that manages complex, large-scale, and continuous processes. It distributes control functions across multiple interconnected controllers instead of relying on a single central unit. Each controller oversees a specific process area, while a supervisory system coordinates overall plant operations.

DCS solutions are widely used in industries such as oil and gas, power generation, chemical processing, and water treatment, where process stability and precision are more important than speed. They are ideal for environments that involve continuous control loops and high reliability requirements.

A DCS includes:

- Field control stations: Handle localized process control and data acquisition

- Engineering and operator workstations: Provide visualization, configuration, and plant monitoring

- Communication network: Connects controllers, HMIs, and servers for seamless data flow

- Historian and supervisory software: Collects, stores, and analyzes process data for optimization and reporting

DCS architectures are built for steady-state process control, integrating thousands of inputs and outputs across large facilities. They offer strong redundancy, advanced control algorithms, and centralized engineering tools that simplify configuration and maintenance.

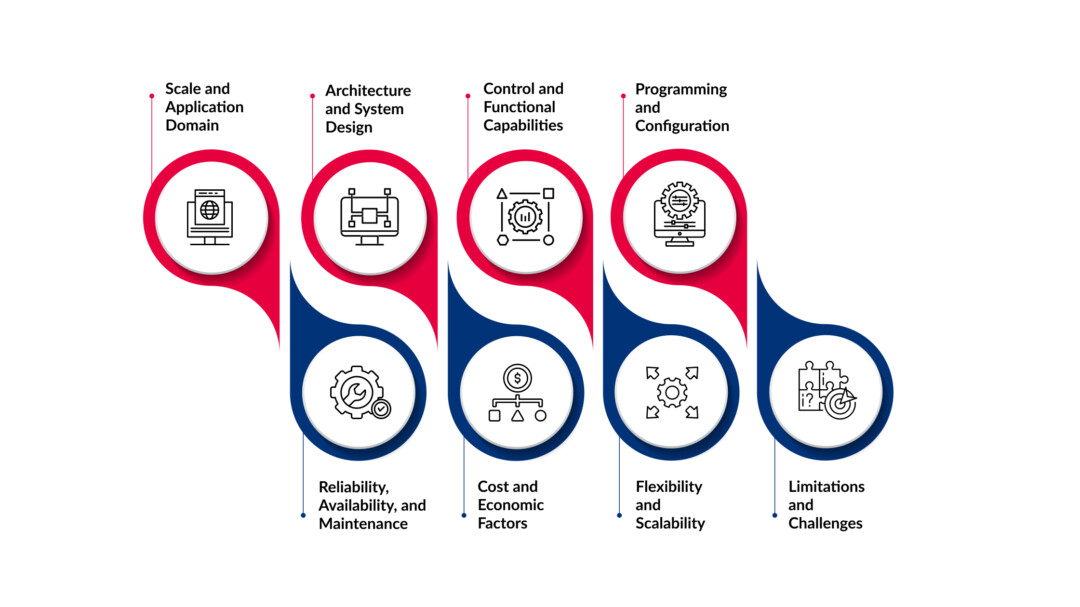

Major Differences Between DCS and PLC

Although both DCS and PLC systems automate industrial operations, their design intent and performance focus are different. PLCs are built for speed, precision, and control of discrete tasks, while DCS systems are structured for stability, coordination, and control of continuous processes.

The differences between the two become most visible when examining system architecture, scalability, programming, and the types of processes they control. Understanding these distinctions enables engineers and decision-makers to select the most suitable system for their operational requirements and long-term objectives.

Scale and Application Domain

The most practical way to distinguish a DCS from a PLC system is to look at where and how each is used. PLCs dominate in discrete manufacturing, where machines perform repetitive tasks in a fixed sequence. DCS systems, on the other hand, are used in process industries, where maintaining steady operation and continuous flow is essential.

PLCs are commonly used in:

- Assembly lines and packaging systems

- Automotive and electronics manufacturing

- Material handling and robotics

- Batch operations with limited control loops

DCS systems are typically deployed in:

- Oil and gas refining and petrochemical plants

- Power generation and water treatment facilities

- Pharmaceutical, pulp and paper, and cement production

- Continuous or semi-continuous process environments

A DCS can handle thousands of input and output points distributed across multiple plant areas, while a PLC generally controls a smaller set of machines or process segments. As a result, PLCs provide faster response times, whereas DCS systems deliver more coordinated control across complex operations.

Architecture and System Design

The architectural design of a PLC and a DCS reflects their different control philosophies. A PLC system is typically centralized, with one or more controllers managing specific machines or production lines. It processes input signals, executes programmed logic, and sends output commands directly to the equipment it controls. Communication between devices is usually point-to-point or through industrial networks.

A DCS, in contrast, uses a distributed structure. Control functions are spread across multiple controllers located near the process areas. Each controller manages its assigned section independently, while a supervisory control layer provides coordination, data visualization, and optimization. This arrangement minimizes communication bottlenecks and allows large facilities to operate efficiently even if a single controller experiences a fault.

Because of this distributed design, a DCS is inherently more scalable and fault-tolerant. It offers integrated redundancy, process historians, and centralized configuration tools that allow engineers to make system-wide updates with minimal disruption. PLC systems, while capable of networking multiple controllers, often require additional software or integration layers to achieve similar coordination.

Control and Functional Capabilities

PLCs excel at executing fast, logic-based control tasks that require quick responses and precision timing. They are often programmed to perform discrete operations such as starting and stopping motors, opening and closing valves, or counting and positioning parts on a production line. Their scan times are short, making them suitable for high-speed manufacturing and machine-level control where immediate feedback is essential.

DCS systems, on the other hand, are optimized for continuous control. They handle analog signals from sensors that measure variables like temperature, pressure, and flow. Each process variable is continuously monitored and adjusted through proportional-integral-derivative (PID) loops to maintain stability.

While PLCs can perform process control through add-on modules or software, their strength remains in sequential and event-driven operations. DCS systems integrate advanced process control, trending, and alarm management directly within their core platform. This makes them better suited for plants that require steady-state control, high reliability, and coordinated operation across multiple process areas.

Programming and Configuration

Programming and configuration mark one of the clearest distinctions between PLCs and DCS systems. PLCs are programmed to execute specific sequences of logic using standardized programming languages defined by IEC 61131-3. These include ladder logic, structured text, and function block diagrams. Each program is designed to control equipment directly and operate in real time. Engineers typically program PLCs for speed, repeatability, and precision in machine-level tasks.

A DCS focuses on process control and system coordination rather than discrete logic. Configuration is performed through an integrated engineering environment where control loops, alarms, and trends are defined and managed centrally. Instead of programming each controller individually, engineers work with templates and process modules that can be reused across the plant.

Common distinctions between PLC and DCS programming include:

- Programming approach: PLCs use logic-based coding, while DCS relies on the configuration of process control strategies.

- Engineering tools: PLCs often require separate software for each controller, while DCS systems provide unified configuration platforms.

- Scalability: Adding new loops or process areas in a DCS requires minimal reprogramming, whereas PLC expansion can involve modifying multiple logic files.

Because of this, PLCs are preferred when flexibility and custom control logic are priorities, while DCS systems are chosen for their ease of management in large-scale, continuous operations.

Reliability, Availability, and Maintenance

Reliability defines how well a control system sustains operation under demanding industrial conditions. PLCs are built for rugged environments and offer excellent uptime at the machine level. Their modular design allows quick replacement of faulty components without shutting down entire systems.

A DCS extends this reliability to the plant level. It uses redundant controllers, communication paths, and power supplies to ensure continuous operation even during hardware failures. Centralized monitoring and diagnostic tools make it easier to detect and resolve issues before they affect production.

Cost and Economic Factors

Cost is often a deciding factor when choosing between a DCS and a PLC system. PLCs generally have lower initial costs, making them attractive for small or mid-sized projects with defined control tasks. Their modular nature allows gradual expansion without major upfront investment.

A DCS requires higher initial capital due to its integrated architecture, redundant hardware, and centralized engineering environment. However, its long-term operational efficiency and reduced downtime can offset these costs in large-scale process industries.

Major cost considerations include:

- Initial investment: PLCs cost less to install and configure, while DCS systems demand higher upfront capital.

- Maintenance and support: PLCs have lower maintenance costs but may need more frequent manual updates.

- System scalability: DCS expansion is smoother and more cost-effective in large facilities compared to upgrading multiple PLC units.

Overall, PLCs suit smaller, discrete applications, while DCS systems become more economical in large plants where reliability, coordination, and centralized control justify the higher investment.

Flexibility and Scalability

PLCs are valued for their flexibility. Engineers can easily modify programs, reassign inputs and outputs, or integrate new devices without major system changes. This adaptability makes PLCs ideal for manufacturing lines that frequently adjust production volumes or switch product configurations.

DCS systems emphasize scalability over flexibility. Their distributed design allows thousands of control loops and input/output points to be added across multiple process areas with minimal configuration effort. Changes are managed through centralized tools that update the entire system consistently.

In short, PLCs offer the agility needed for fast-changing operations, while DCS systems deliver the scalability required to manage large, complex, and continuous industrial environments.

Limitations and Challenges

Both DCS and PLC systems have practical limitations that influence where they are best applied.

PLCs, while fast and reliable, become harder to manage as system size grows. Coordinating multiple PLCs across a large facility often requires additional software layers or SCADA integration. They also offer limited built-in redundancy, which can increase downtime risk in critical operations.

DCS systems, on the other hand, are complex and expensive to implement. Their centralized engineering tools and integrated architecture require specialized expertise. Updates, licensing, and vendor support can add to long-term costs. For smaller or rapidly changing production environments, a DCS may be more than what the process demands.

Selecting Between DCS and PLC: Decision Criteria

Choosing between a DCS and a PLC depends on the nature of the process, operational goals, and available resources. Each system has strengths that make it more suitable for certain environments. The decision is not only about technology but also about the scale, complexity, and reliability requirements of the plant.

| Criterion | PLC | DCS |

| Process Type | Best for discrete, sequential, and machine-level control | Ideal for continuous or batch process control |

| System Scale | Small to medium | Large and complex |

| Response Time | Fast scan cycles for real-time control | Moderate response suited for continuous regulation |

| Architecture | Centralized control with limited redundancy | Distributed architecture with built-in redundancy |

| Programming | Logic-based programming (Ladder, Structured Text) | Configuration-based control with process templates |

| Cost | Lower initial investment | Higher upfront cost, lower long-term operational risk |

| Maintenance | Component-level maintenance | Centralized monitoring and diagnostics |

| Scalability | Manual integration required for expansion | Seamless addition of controllers and I/O points |

| Operator Interface | Basic HMI or SCADA connection | Fully integrated operator and engineering stations |

| Best Fit | Discrete manufacturing, assembly, packaging | Process industries like oil, gas, and power generation |

Upgrade Your Industrial Automation with LS Electric America Inc.

Selecting the right automation system shapes the efficiency, safety, and growth potential of every industrial operation. PLCs excel in fast, logic-based control, while DCS systems manage large-scale, continuous processes with precision and reliability. Both play a crucial role in achieving consistent, optimized performance.

LS Electric America Inc. provides a comprehensive range of automation solutions that bring control, flexibility, and insight to every level of industrial operation. Our major products include:

- Programmable Logic Controllers (PLCs): Efficiently manage and automate machinery and process control tasks.

- LV Drives: Adjust and optimize motor speed for energy efficiency and smoother operation.

- Servo Systems: Deliver precise motion control for high-performance equipment.

- Human Machine Interfaces (HMIs): Offer real-time monitoring and intuitive interaction with devices and systems.

From unit-level devices to full process control, LS ELECTRIC helps industries operate with greater stability and performance.

Explore LS Electric’s automation portfolio and discover how integrated control technologies can enhance productivity and streamline plant operations.