What’s powering the factories, energy grids, and water systems of the future? It’s not just machines; it’s intelligent automation.

In modern industrial operations, even a single minute of downtime can lead to significant financial loss, making automation essential for maintaining efficiency and control.

According to Deloitte, manufacturers using innovative automation technologies report up to 20% improvement in equipment uptime and 30% reduction in operating costs. However, unlocking these benefits starts with understanding the core systems behind automation.

Two significant technologies are at the core of these systems: PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition). Both are fundamental to modern industrial automation but serve different purposes.

A PLC is designed to control machinery and processes in real time. It responds immediately to input signals, executes programmed logic, and controls output devices such as motors, valves, and alarms.

In contrast, an SCADA system is used for monitoring and supervision. It collects data from multiple devices, including PLCs, displays that information to operators, and allows centralized oversight and analysis.

This blog directly compares SCADA vs PLC, explaining their functions, differences, and how they work together in real-world environments. Whether you’re building new infrastructure or upgrading existing systems, knowing when to use PLCs, SCADA, or both can help you design more efficient, scalable, and reliable automation solutions.

What is a Programmable Logic Controller?

A Programmable Logic Controller (PLC) is a specialized industrial computer that controls machinery and processes in manufacturing, assembly lines, and other automation applications.

A PLC is a digital controller that receives input data from connected sensors or devices, processes this data based on user-defined instructions (the program), and sends output commands to actuators or machinery. Its primary purpose is to automate repetitive tasks and decision-making processes, improving precision, efficiency, and safety in industrial systems.

PLCs are widely used to control production equipment like motors, valves, lights, and pumps, monitor system performance, and coordinate machine-to-machine interactions without human intervention.

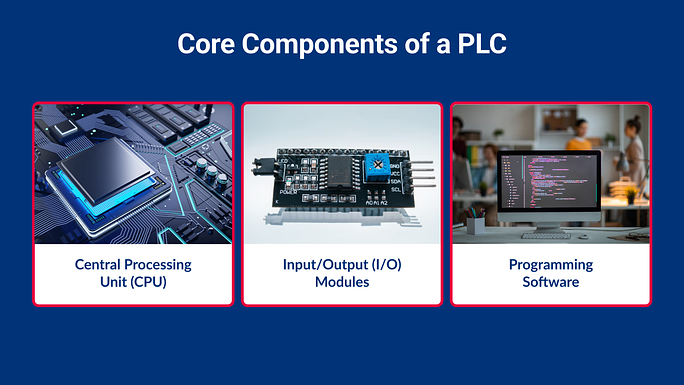

Core Components of a PLC

Each PLC system includes several essential components, each playing a distinct role in ensuring effective automation.

-

Central Processing Unit (CPU)

The CPU is the brain of the PLC. It performs the logic execution, processes input data, executes the user-written program, and updates output devices accordingly. It also handles internal diagnostics, system communication, and memory management.

-

Input/Output (I/O) Modules

I/O modules serve as the interface between the PLC and external devices. Input modules receive signals from sensors, switches, and other field devices. These could be digital (on/off) or analog (variable signals like temperature or pressure).

Output modules send commands to actuators like motors, solenoids, relays, and lamps. Depending on the system design, these modules can be integrated within the PLC (compact type) or separately (modular type).

-

Programming Software

Programming software allows engineers or technicians to write, test, and upload logic instructions to the PLC. Most PLCs use Ladder Logic, a graphical programming language resembling electrical relay circuits. Other languages, depending on the application and PLC manufacturer, include function block diagrams (FBD), structured text (ST), and instruction list (IL).

Primary Functionalities of a PLC System

Here are the core functionalities of a PLC system, each enabling precise and reliable automation control in industrial environments:

- Real-Time Control: Executes commands instantly to manage machinery and equipment.

- Signal Processing: Handles both digital and analog input/output signals.

- Logic Execution: Runs programmed logic for process control and automation.

- Loop Control: Manages feedback loops using PID or other control methods.

- System Integration: Communicates with SCADA, HMIs, and other controllers.

- Fault Detection: Identifies errors and alerts operators for quick resolution.

- Program Flexibility: Easily reprogrammed and scalable for future needs.

What is Supervisory Control and Data Acquisition?

Supervisory Control and Data Acquisition (SCADA) is a software-based control system used in industrial environments to monitor, gather, and process real-time data from remote locations. It gives operators a centralized interface to observe process status, respond to alarms, and make data-driven decisions.

Unlike PLCs, which directly control machinery, SCADA systems supervise multiple PLCs and other field devices across an entire facility or geographically distributed sites. SCADA enables human operators to interact with automation systems through graphical interfaces and dashboards.

SCADA is essential in industries where operations span broad areas (e.g., utilities, pipelines), centralized monitoring of multiple field devices is required, and human intervention is needed for decision-making.

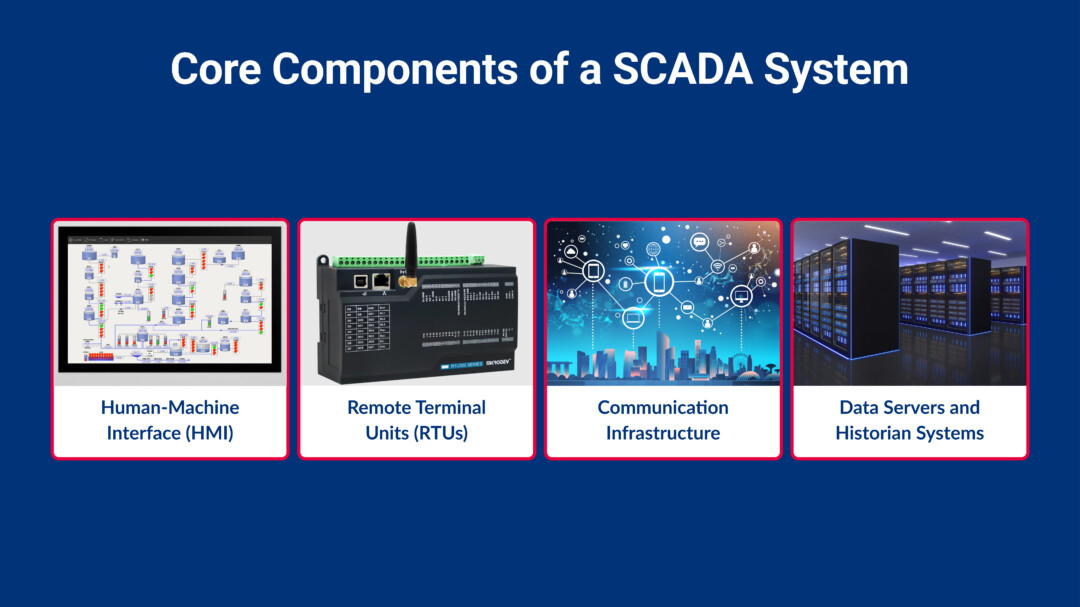

Core Components of a SCADA System

A SCADA system is composed of several interdependent components, each playing a specific role in the flow and presentation of data.

-

Human-Machine Interface (HMI)

The HMI user interface allows operators to interact with the system. It provides graphical representations of equipment, real-time status indicators, trend graphs, and alert notifications.

This displays data from field devices in user-friendly formats and allows annual override of control operations.

-

Remote Terminal Units (RTUs)

RTUs are microprocessor-based devices that collect sensor data from the field and transmit it to the SCADA system. They can also execute limited control functions. It is often used in remote or hazardous locations and can communicate via telemetry (radio, satellite, or cellular networks).

These help to collect analog and digital data, such as temperature, flow rate, or valve status.

-

Communication Infrastructure

This network layer connects field devices (PLCs/RTUs) to the central SCADA server and HMIs, ensuring seamless and reliable data transmission.

Ethernet, fiber optics, serial links, radio, or wireless protocols can be used. Critical operations require redundancy and security (e.g., VPNs, firewalls). Protocols like Modbus TCP/IP, DNP3, or OPC UA may be used.

-

Data Servers and Historian Systems

The data server stores, organizes, and processes the system’s real-time and historical data. The historian archives long-term data for analysis and reporting. These servers help to store time-stamped data for regulatory compliance and audits.

Primary Functionalities of a SCADA System

SCADA provides a range of functions critical to industrial management:

- Data Collection: Continuously gathers real-time information from field sensors and devices.

- Visualization: Displays data graphically via HMI dashboards for quick decision-making.

- Alarm Management: Notifies operators of abnormal conditions (e.g., pressure drops, high temperature) so immediate action can be taken.

- Remote Monitoring and Control: Enables operators to manage field equipment from centralized or off-site locations.

- Historical Data Logging: Records process trends, operator actions, and alarm events for diagnostics and reporting.

SCADA vs PLC: Understanding the Differences

Understanding the fundamental differences between PLC and SCADA systems is crucial for selecting the right solution in industrial automation. While both are integral components, they serve distinct roles. Below is a detailed explanation of the core differences between SCADA vs PLC across key functional areas.

-

Control vs. Supervision

A PLC (Programmable Logic Controller) directly controls industrial equipment. It reads input signals from sensors or switches and activates output devices like motors or actuators based on the programmed logic. Its role is to execute predefined control tasks such as turning devices on or off, managing sequences, and responding to real-time inputs.

In contrast, SCADA (Supervisory Control and Data Acquisition) systems are focused on supervisory functions. They collect data from various PLCs and other devices, display it to human operators, and allow for high-level control and monitoring. SCADA systems do not directly control hardware but provide interfaces and tools for overseeing multiple processes.

-

Hardware vs. Software

PLCs are primarily hardware-based devices. They are built with input/output modules, processors, and memory, and they run embedded software to perform control tasks. Their design is optimized for reliability and durability in industrial environments.

SCADA systems, on the other hand, are largely software-based. They typically operate on standard computers or servers and interface with field devices through communication protocols. The core of a SCADA system includes data acquisition software, human-machine interfaces (HMIs), and historical databases.

-

Real-time Operation

PLCs are designed for real-time operation. They continuously scan input data, execute logic, and update outputs with minimal delay. This rapid cycle time allows them to respond instantly to changes in process conditions, which is critical for safety and operational accuracy.

SCADA systems also work with real-time data, focusing on visualization and analysis rather than direct control. They display system statuses in real time, generate alarms for operators, and store historical data for trend analysis and reporting. Their response time is sufficient for supervision but not for high-speed control.

-

Scalability

PLCs are deployed for specific and localized control tasks. They are well-suited for automating individual machines or small-scale processes. While multiple PLCs can be networked, they operate independently unless integrated into a larger system.

SCADA systems are designed for large-scale monitoring and control. They can manage hundreds or thousands of data points from multiple PLCs and remote devices across a wide geographical area. SCADA platforms are scalable and can be expanded to accommodate growing operations or additional system components.

How Do PLC and SCADA Work Together In Automation Systems?

In modern industrial automation, PLC and SCADA systems coordinate for efficient, real-time process control and monitoring. Here is how they operate:

1. Role of PLCs in SCADA-Based Systems

PLCs act as data acquisition units within the SCADA architecture. They are installed on-site near machinery or equipment and are responsible for:

- Collecting data from sensors (e.g., temperature, pressure, proximity).

- Executing control logic to operate devices like motors, pumps, and valves.

- Sending process data (inputs, outputs, internal variables) to the SCADA system.

- Receiving supervisory control instructions from SCADA when needed (e.g., to start/stop a process).

PLCs work independently but are integrated with the SCADA layer to enable centralized visibility and coordination across multiple devices or subsystems.

2. SCADA’s Function in the Combined System

SCADA systems do not control machinery directly. Instead, they:

- Read data from multiple PLCs across the plant or facility.

- Display information through HMIs (Human-Machine Interfaces).

- Monitor system performance using real-time dashboards and alarms.

- Log historical data for reporting and analysis.

- Enable remote control actions like resetting faults or modifying setpoints by sending commands to PLCs.

SCADA allows operators and supervisors to manage large-scale systems efficiently through a single centralized platform, even if the physical equipment is widely distributed.

3. Communication Protocols Between PLC and SCADA

Industrial communication protocols exchange information reliably for PLCs and SCADA systems. These protocols define how devices send and receive data over a network. Commonly used protocols include:

- MODBUS (RTU and TCP/IP)

- Open protocol used for serial (RS-232/RS-485) and Ethernet communication.

- Simple and widely supported by PLCs and SCADA software.

- Transmits data in a master-slave configuration.

- Ethernet/IP

- Based on standard Ethernet but optimized for industrial use.

- Allows high-speed, real-time data exchange.

- Commonly used in Allen-Bradley and Rockwell Automation environments.

- Profibus and Profinet

- Developed by Siemens for industrial automation.

- Profibus (Process Field Bus) is used for serial communication.

- Profinet is its Ethernet-based successor, offering better speed and scalability.

These protocols ensure that PLCs can transmit data to SCADA software without errors or delays, and that SCADA can send supervisory commands back to PLCs as needed.

Real-World Applications of PLC and SCADA

PLCs and SCADA systems are widely used across industries to improve efficiency, ensure safety, and enable remote monitoring. Below are essential sectors where these technologies play an indispensable role:

-

Manufacturing Industry

PLCs control assembly lines, packaging systems, and robotic arms in manufacturing. They ensure that processes are synchronized and operate within defined parameters. SCADA systems monitor these operations in real-time, track production metrics, and help identify issues like bottlenecks or equipment failures.

-

Energy Sector

In the energy sector, PLCs control breakers, transformers, and other critical components in substations and power plants. SCADA systems provide centralized monitoring of the entire grid, allowing operators to observe energy flow, respond to faults, and optimize load distribution across different regions.

-

Water Management

PLCs handle pump operation, valve control, and chemical dosing tasks for water and wastewater treatment facilities. SCADA systems collect data from these devices, visualize flow rates, pressure levels, and tank capacities, and alert operators to anomalies or required maintenance actions.

-

Transportation

In transportation, PLCs manage traffic light sequences, railway signal control, and gate operations. SCADA systems oversee the overall traffic network, monitor congestion, and control signaling infrastructure remotely, improving coordination and safety across transit systems.

Explore the Future of Industrial Automation with LSElectric America Inc.

As industries transition to more brilliant, interconnected systems, LSElectric America Inc. is leading the charge by providing innovative and reliable solutions for both PLC and SCADA systems, designed to enhance control, monitoring, and efficiency across all levels of industrial automation.

Whether you’re integrating PLC-based control panels, advanced SCADA systems for real-time monitoring, or leveraging our power distribution and automation solutions, we offer a full range of products to streamline operations, improve decision-making, and drive long-term efficiency.

Our solutions include:

Future-proof your operations and stay ahead in industrial automation.