Industrial and electrical systems leave little room for error. Just a momentary power disruption can trigger costly downtime.

When designing control panels and power systems, the choice between connection architectures, such as terminal blocks and bus bars, significantly impacts space efficiency, system reliability, maintenance overhead, and overall cost.

In this blog, we’ll discuss the differences between terminal blocks and bus bars, their respective benefits, and how to determine which solution best suits your application. Because when every millisecond and every connection point matters, informed choices pay off.

What Are Terminal Blocks?

Terminal blocks are modular, insulated components used to connect and organize electrical conductors within control panels and power distribution systems. They provide a safe, clean, and service-friendly way to route electricity without splicing wires, making them a go-to solution for industrial automation, machinery, and building electrical infrastructure.

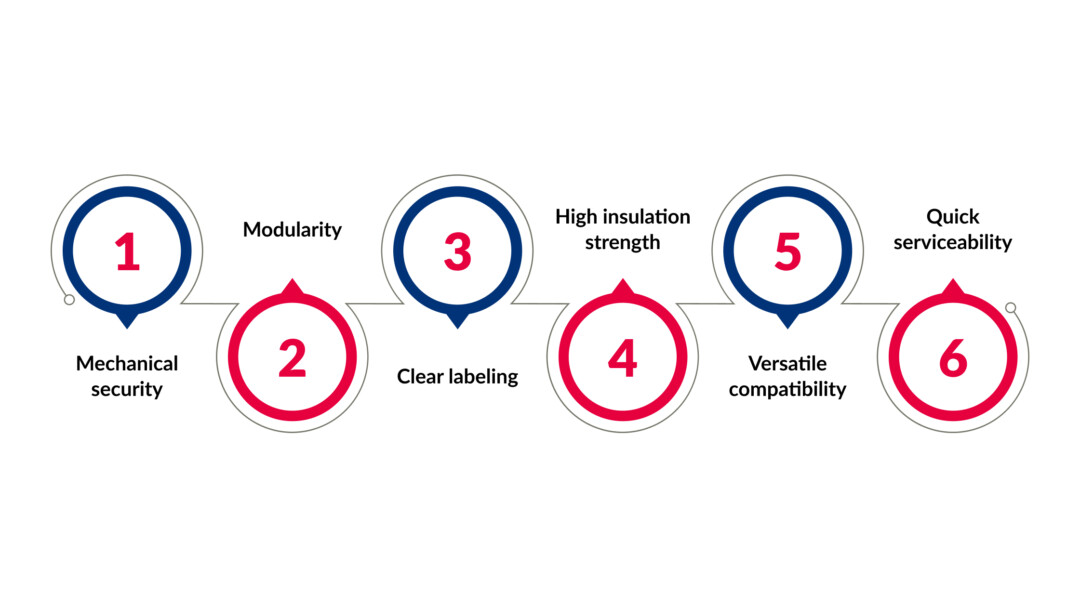

Major Features of Terminal Blocks:

What Are Terminal Blocks_

- Mechanical security: Screws, clamps, or spring mechanisms hold wires firmly in place

- Modularity: Blocks can be added, removed, or rearranged to fit installation needs

- Clear labeling: Marking strips help prevent wiring mistakes and simplify maintenance

- High insulation strength: Protects against accidental shorts and electrical hazards

- Versatile compatibility: Accepts a wide range of wire sizes and terminal styles

- Quick serviceability: Faulty blocks can be replaced without disturbing the entire circuit

Terminal blocks provide the structure and safety necessary for organized, reliable power distribution, particularly when constant system access is anticipated.

What Are Bus Bars?

Bus bars are metallic conductors, commonly made of copper or aluminum, that efficiently distribute large amounts of current within electrical power systems. They act as central pathways that consolidate multiple circuits, reducing wiring complexity and improving energy transfer performance across switchgear, transformers, control panels, and distribution boards.

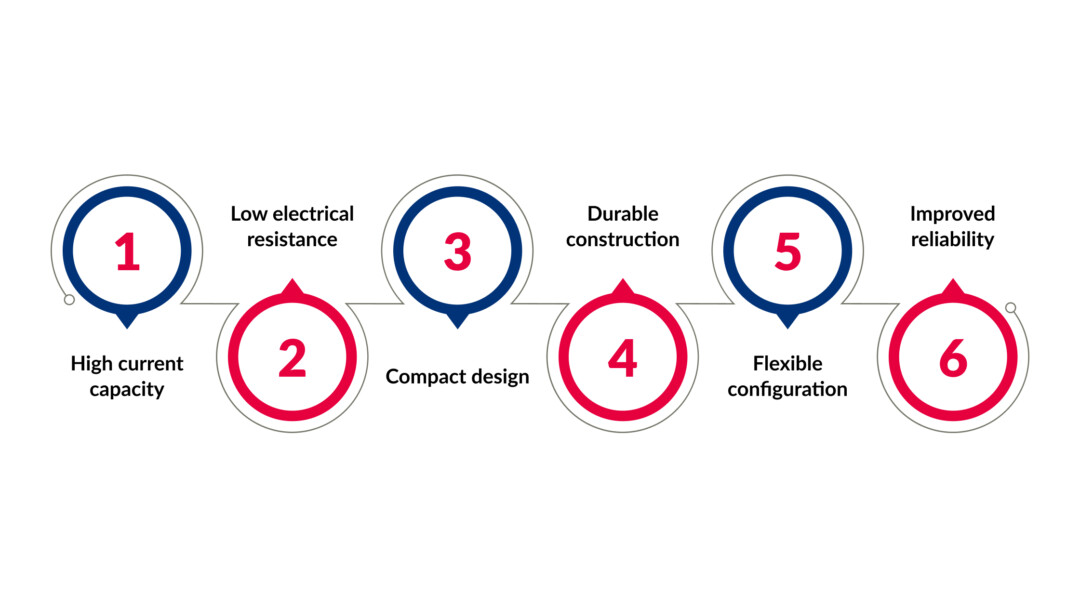

Primary Features of Bus Bars:

Primary Features of Bus Bars

- High current capacity: Supports heavy electrical loads with minimal power loss

- Low electrical resistance: Enhances efficiency and reduces heat generation

- Compact design: Eliminates bulky wiring and helps optimize panel space

- Durable construction: Resists corrosion and withstands harsh industrial environments

- Flexible configuration: Available in various shapes and layered arrangements

- Improved reliability: Reduces connection points that often cause failures

Bus bars bring strength and scalability to power distribution, making them the preferred choice in systems where high performance and efficiency are non-negotiable.

Differences Between Terminal Blocks vs Bus Bars

Terminal blocks and bus bars may appear interchangeable at first glance, both acting as power distribution components. Yet their purpose, structure, and performance are far from identical. A closer look reveals how each supports electrical systems differently and why choosing the wrong one can cause space issues, overheating risks, or unnecessary installation complexity. Let’s break down how they differ.

| Feature | Terminal Blocks | Bus Bars |

| Connection Method | Screw, spring clamp, push-in connectors | Bolted or welded joints, plug-in systems |

| Insulation Requirements | Each block includes its own insulation housing | Requires external insulation or encapsulation |

| Marking and Identification | Easy labeling for circuit tracking | Requires custom tagging/labeling by section |

| Fault Isolation | Individual circuits can be quickly isolated | Faults may affect larger distribution sections |

| Customization | Can add accessories: jumpers, test sockets, fuses | Custom shapes, coatings, and mounting styles |

| Maintenance Complexity | Simple to inspect or replace single connections | Requires skilled handling due to high current |

| Thermal Performance | Less effective heat dissipation due to compact wiring | Superior heat dissipation thanks to a large conductive surface |

| Vibration Resistance | May loosen over time if screw-type blocks are used | Stronger structural integrity in high-vibration settings |

1. Power Handling Capabilities

Terminal blocks support organized wiring and safe termination, though their current-carrying capacity is generally limited due to their smaller contact surface and reliance on individual clamping connections. They work best in low- to moderate-power circuits where precise wiring and segmented distribution are priorities.

Bus bars, however, excel at carrying high currents efficiently. Large conductive surfaces, typically copper or aluminum, allow greater ampacity with reduced heat buildup and lower voltage drop. They deliver power to multiple outputs without the bottleneck created by multiple screw-type terminations.

2. Space Requirements

Terminal blocks take up more room because each conductor requires an individual termination point, often arranged in long rows on DIN rails. As circuits scale, panel layouts can become dense and require meticulous routing to avoid clutter, especially in large control systems.

Bus bars provide a more compact power distribution solution. Their ability to consolidate many connections into a single conductive bar reduces wiring bulk and frees valuable cabinet space. This becomes crucial in high-density applications such as switchgear, EV infrastructure, or power distribution units, where every centimeter counts.

3. Flexibility and Modularity

Terminal blocks excel when frequent changes, expansions, or maintenance updates are expected. Each wire can be individually inserted, labeled, or replaced, giving engineers precise control over circuit organization. Modular block designs allow easy additions that simply snap in another block and continue the wiring path. This flexibility makes terminal blocks a favorite in control panels that change over time.

Bus bars, on the other hand, are less adaptable once installed. They typically serve fixed, high-current distribution paths with standardized connection points. Modifying a bus bar setup often requires mechanical rework or the addition of components, such as tap-off points or multi-layer structures. As a result, bus bars offer efficient power distribution but not the same degree of modular reconfiguration that terminal blocks provide.

4. Cost Considerations

Terminal blocks typically offer a lower upfront cost, especially in systems with many individual circuits but modest current levels. Their installation is straightforward, and replacements or additions can be made without requiring major structural changes, which helps reduce maintenance expenses over time. However, in applications requiring dense wiring, the cumulative cost of multiple blocks and panel space may add up.

Bus bars involve a higher initial investment due to their robust conductive materials and customized fabrication requirements. Yet, for high-current environments, they can be more economical in the long run. Bus bars minimize voltage drops, reduce wiring complexity, and streamline installation, benefits that can lower total lifecycle costs.

The financial decision ultimately depends on load levels, design scale, and future expansion needs.

5. Suitability for Different Applications

Terminal blocks and bus bars are designed to align with specific operational needs. Terminal blocks excel where wiring organization and flexibility are crucial, while bus bars shine when power density and efficient load handling are the top priorities.

Terminal Block Applications

Terminal Block Applications

- Control Panels: Clear circuit organization enables efficient troubleshooting and service work.

- Automation & Instrumentation: Supports numerous signal connections in compact layouts.

- Machinery & Equipment Wiring: Allows quick disconnection and reconnection during upgrades or repairs.

- Facilities Requiring Frequent Modifications: Modular design simplifies future expansion and changes.

Bus Bar Applications

Bus Bar Applications

- High-current Distribution Systems: Safely handle large power loads with minimal energy loss.

- Switchgear & Power Distribution Centers: Reduce wiring congestion while maintaining structural integrity.

- Data Centers & Large Commercial Buildings: Efficiently manage rising energy demands in tight spaces.

- Renewable Energy & Substations: Enhance conductivity and reliability in demanding electrical environments.

Terminal blocks focus on precision, accessibility, and ease of maintenance; bus bars prioritize efficiency, heat management, and large-scale power delivery.

Configure the Right Power Infrastructure With LSElectric America Inc. Experts

Configure the Right Power Infrastructure With LSElectric America Inc. Experts

Choosing the right power distribution solution directly shapes long-term performance, safety, and scalability. Terminal blocks and bus bars both have important roles to play, and selecting the ideal option depends on current capacity, layout needs, and maintenance considerations.

LSElectric America Inc. helps engineers and facility leaders build smarter, safer, and more efficient power systems through advanced technologies across:

- Panel Control: Precise and reliable wiring infrastructure

- Automation & Drives: Flexible control for industrial efficiency

- Power Distribution: Comprehensive devices for dependable energy flow

Stronger control. Cleaner distribution. Better uptime.

Get the right-fit solution for your next installation or upgrade.