Power outages in the United States have been increasing at an alarming rate. Surprisingly, Inside Energy reported that from 2000 to 2014, the annual average of outages doubled every five years, highlighting a growing concern for businesses and industries.

As power disruptions become more frequent, they lead to operational delays, equipment failures, and costly downtime, making electrical reliability extremely critical.

Ensuring a stable power supply isn’t just about generation—it also depends on reliable protection systems like circuit breakers that prevent faults from causing widespread failures.

Among them, vacuum circuit breakers (VCBs) stand out for their efficiency, durability, and low maintenance. Using a vacuum to stop electrical arcs ensures safe and reliable power switching for industries, substations, and commercial facilities.

But what makes VCBs different from other circuit breakers? How do they work, and why are they preferred for modern power grids?

This blog will discuss the working principles, benefits, and applications of vacuum circuit breakers, highlighting their role in maintaining a stable and efficient electrical infrastructure.

What is a Vacuum Circuit Breaker?

| A vacuum circuit breaker (VCB) is an electrical switching device that interrupts the current flow in a circuit using a vacuum as the arc-extinguishing medium. Unlike other breakers that rely on gas or oil, VCBs create an almost perfect vacuum to quench the electrical arc. |

When a fault occurs, the breaker contacts separate, forming an arc. This arc is quickly extinguished in a vacuum because no gases or particles sustain it. This ensures rapid fault isolation and system protection.

VCBs are commonly used in medium-voltage applications (1 kV to 38 kV). They provide reliable switching and protection in electrical networks, reducing downtime and enhancing grid stability.

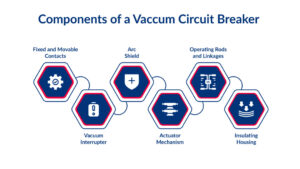

Components of a Vaccum Circuit Breaker

A vacuum circuit breaker (VCB) consists of several critical components that work together to interrupt electrical current safely and efficiently. Below are the major components:

Fixed and Movable Contacts

The fixed contact is a stationary component that allows current to flow when the breaker is closed, while the movable contact connects and disconnects from it to control electricity flow. Under normal conditions, these contacts remain closed, enabling uninterrupted power transmission. However, during a fault, the breaker mechanism separates the contacts to interrupt the circuit.

Vacuum Interrupter

The vacuum interrupter, a sealed chamber that houses the contacts, is at the core of a VCB. When the contacts separate, metal vapors ionize, forming an arc. However, no gases or particles sustain the arc in a vacuum, causing it to extinguish almost immediately. This process ensures minimal energy loss and rapid current interruption.

Arc Shield

The arc shield protects the vacuum chamber from contamination by metal vapors generated during contact separation. This enhances the vacuum interrupter’s reliability and longevity, ensuring consistent breaker performance over multiple operations.

Actuator Mechanism

The actuator mechanism moves the breaker’s contacts during operation. It can be spring-operated, electromagnetic, or motor-driven. This mechanism ensures a rapid response to faults such as short circuits and overcurrent, swiftly isolating electrical faults and preventing system damage.

Operating Rods and Linkages

The operating rods and linkages transfer the motion from the actuator mechanism to the movable contact. These components ensure precise movement, allowing the breaker to function efficiently with minimal wear and tear.

Insulating Housing

The insulating housing provides mechanical support and electrical insulation for internal components. Typically made of ceramic or glass, it helps maintain the vacuum seal and withstands high voltages, ensuring the breaker’s safe operation.

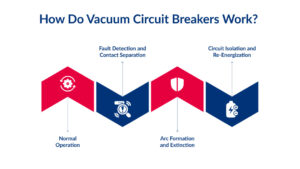

How Do Vacuum Circuit Breakers Work?

The operation of a vacuum circuit breaker follows a systematic sequence to ensure effective fault isolation:

Normal Operation

The fixed and movable contacts remain closed in normal conditions, allowing uninterrupted current flow through the circuit. The vacuum interrupter maintains a high dielectric strength, preventing unintended discharges.

Fault Detection and Contact Separation

When a fault occurs—such as an overcurrent or short circuit—the breaker detects the abnormality and activates the actuator mechanism. This causes the movable contact to separate from the fixed contact, breaking the circuit.

Arc Formation and Extinction

As the contacts separate, an arc forms due to ionized metal vapors. However, in a vacuum, the absence of gases prevents the arc from sustaining. The arc extinguishes quickly as the metal vapors condense back onto the contact surfaces, restoring the vacuum’s dielectric strength.

Circuit Isolation and Re-Energization

The circuit remains open once the arc is extinguished, preventing further current flow and isolating the fault. After troubleshooting and resolving the issue, the breaker can be re-closed to restore power safely.

Advantages of Vacuum Circuit Breakers

Vacuum circuit breakers (VCBs) are widely used for their efficiency, reliability, and safety. They offer superior arc quenching, minimal maintenance, and long service life. Unlike regular breakers, VCBs do not rely on gas or oil, making them environmentally friendly. Their compact design and fast operation make them ideal for modern electrical systems.

Efficient Arc Quenching

VCBs use a vacuum to extinguish the arc quickly. The absence of gas or other mediums ensures minimal energy loss and prevents damage to electrical contacts. This reduces downtime caused by electrical faults, helping businesses maintain uninterrupted operations and avoid costly repairs or equipment replacements.

Low Maintenance

Unlike oil or gas circuit breakers, VCBs require little maintenance. Gas refilling or oil replacement is unnecessary, lowering operational costs. Businesses benefit from reduced maintenance labor, fewer service interruptions, and lower long-term expenses, contributing to higher profitability.

Compact and Lightweight

VCBs are smaller and lighter than conventional breakers, making installation easier. Their compact design is helpful in space-constrained environments like industrial plants and commercial buildings. This advantage allows businesses to optimize space usage, reduce infrastructure costs, and simplify electrical panel designs in modern facilities.

Environmentally Friendly

Sulfur hexafluoride (SF₆) is a potent greenhouse gas, with a global warming potential 23,500 times that of CO₂ over 100 years. Unlike SF6 circuit breakers, which use greenhouse gases, vacuum circuit breakers (VCBs) operate without the use of SF₆, eliminating concerns about harmful emissions. This makes VCBs a more environmentally friendly and sustainable option for power grids.

High Reliability in Frequent Switching

VCBs can handle frequent switching without performance degradation, making them ideal for industrial applications and power distribution systems. Businesses that require high power reliability, such as manufacturing plants and data centers, benefit from improved electrical stability, reduced risk of outages, and extended equipment lifespan.

These advantages make vacuum circuit breakers preferred for reliable and sustainable power distribution.

Applications of Vacuum Circuit Breakers

Vacuum circuit breakers (VCBs) protect electrical systems from faults and ensure reliable power distribution. VCBs are major in maintaining electrical stability and safety from power plants to commercial buildings.

-

Power Generation Plants

VCBs are widely used in power plants to safeguard critical equipment such as generators and transformers. They help prevent faults from damaging expensive machinery, ensuring uninterrupted electricity production and distribution. Their ability to handle high-voltage switching makes them essential in power generation facilities.

-

Industrial Facilities

Manufacturing plants, steel mills, and refineries rely on VCBs to protect motors, conveyors, and heavy machinery. Frequent switching operations in industrial settings demand a durable solution, and VCBs excel due to their long service life and minimal maintenance. They prevent unexpected shutdowns and equipment failures, improving operational efficiency.

-

Electrical Substations

Substations are crucial for distributing electricity across cities and industries. VCBs protect transformers, circuit networks, and distribution lines from short circuits and overloads. Their quick fault isolation ensures stable power transmission, reducing the risk of widespread outages.

-

Railway Systems

VCBs are essential for the smooth and safe operation of electrified railway networks. They help protect train power supply systems from electrical faults, preventing service disruptions and ensuring passenger safety.

-

Commercial Buildings

VCBs are used for safe power distribution in shopping malls, hospitals, office complexes, and other commercial spaces. Their compact design and high reliability make them ideal for installations where space and efficiency are priorities.

-

Renewable Energy Systems

Wind farms and solar power plants require reliable circuit breakers for power fluctuations. VCBs ensure smooth operation by protecting electrical infrastructure from faults, supporting the growth of sustainable energy solutions.

Factors to Consider When Selecting the Right Vacuum Circuit Breakers for Power Grids

When selecting vacuum circuit breakers (VCBs) for power grids, it’s essential to consider several critical factors to ensure optimal performance and safety:

- Voltage Rating: To prevent insulation breakdown and other issues, ensure the VCB’s voltage rating matches the system’s voltage level.

- Current Rating: The VCB must handle the system’s peak current without overheating or damage. Evaluate both continuous and short-circuit current ratings to ensure effective fault interruption.

- Interrupting Capacity: This defines the maximum fault current the VCB can safely interrupt. Selecting a breaker with adequate interrupting capacity is vital for system protection.

- Mechanical and Electrical Endurance: Consider the VCB’s durability by assessing its rated operational cycles. A higher endurance rating indicates longer service life and reduced maintenance.

- Operating Mechanism: VCBs utilize various mechanisms, such as spring-operated or electromagnetic actuators. The choice depends on factors like operation frequency and required response time.

Future of Vacuum Circuit Breakers

The future of vacuum circuit breakers (VCBs) looks promising, driven by advancements in grid modernization, renewable energy integration, and the demand for efficient power distribution. The global VCB market is expected to reach $1.7 billion by 2032, growing at a CAGR of 5.8%. This growth is fueled by increasing electricity demand, modernization efforts, and the transition to sustainable energy solutions. The factors affecting the growth of VCBs include:

Renewable Energy Expansion: As wind and solar power adoption rises, VCBs ensure stable power distribution by efficiently handling grid fluctuations.

Grid Modernization & Smart Grids: With fast fault-clearing capabilities, VCBs enhance grid stability and seamlessly integrate into automated electrical networks.

Urbanization & Industrialization: The growing demand for electricity in industries and residential areas makes VCBs essential for reliable power protection.

Eco-Friendly & Sustainable Solutions: Free from harmful gases, VCBs align with global environmental regulations, promoting greener energy solutions.

Protect Your Power Systems with LSElectric America Inc.

When it comes to protecting your electrical systems and ensuring operational safety, LSElectric America Inc. leads the way with an advanced Vacuum Circuit Breaker (VCB) that meets the highest industry standards. Our cutting-edge VCBs provide superior arc quenching, fast fault clearing, and long-term reliability for seamless power protection.

Whether you need efficient fault interruption, enhanced system stability, or eco-friendly solutions, our VCBs are engineered for optimal performance.

Our offerings include:

Our VCB solutions are ideal for industrial, commercial, and utility applications because they focus on durability, efficiency, and ease of integration.

Partner with LSElectric America Inc. today to strengthen your power infrastructure with reliable vacuum circuit breakers.