As global industries scale and electrification accelerates, the pressure on electrical infrastructure is reaching new highs. From data centers and EV chargers to high-speed rail systems and manufacturing plants, modern power systems demand faster, safer, and more space-efficient distribution than ever before.

In fact, global electricity consumption is projected to surge by over 52% by 2050, according to the U.S. Energy Information Administration (EIA). That exponential growth means conventional wiring methods cannot keep up with the demanding performance, safety, and scalability expectations.

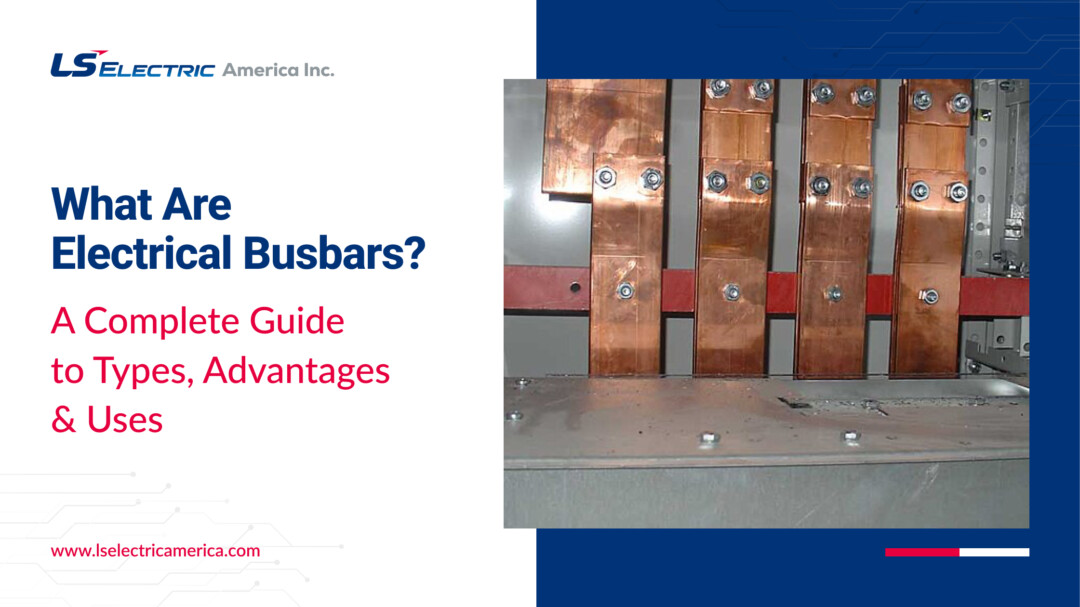

Electrical busbars have emerged as a critical solution, offering a compact, low-resistance conductor that simplifies layouts, enhances thermal management, and ensures reliable power flow in applications ranging from substations to robotics. Whether designing switchgear for a smart factory or upgrading a hospital’s electrical panel, busbars have become an essential component in modern electrical systems.

In this blog, we’ll break down:

- What busbars are and how they work

- Major types and when to use them

- Their structure and components

- Real-world applications across sectors

- The performance and safety advantages they offer

What Is an Electrical Busbar?

| An electrical busbar is a metallic strip or bar that carries large currents within electrical distribution systems. Made from copper or aluminium, busbars provide a low-impedance pathway to distribute power efficiently between circuits or components. |

Rather than relying on bulky wiring systems, busbars offer a streamlined alternative that reduces clutter, minimizes voltage drop, and simplifies layout. Their flat, compact shape enables them to handle high current loads with improved heat dissipation compared to traditional cables.

Busbars are commonly used in:

- Switchboards and switchgear

- Distribution panels

- Substations

- Industrial control equipment

They support three-phase and single-phase systems, and their structure can vary based on the current rating, fault tolerance, and physical layout of the installation. Due to their mechanical rigidity and electrical conductivity, busbars enable engineers to design systems that are easier to scale, inspect, and maintain, particularly in environments where space and performance are crucial.

Common Functions of a Busbar

The busbar serves multiple essential functions that support safe, efficient, and reliable electrical performance. Its design may appear simple, but its role is anything but.

Here are the important functions of a busbar:

Power Distribution: Busbars distribute electrical power from a source, such as a transformer or generator, to multiple outgoing circuits. This centralized pathway helps manage load distribution with minimal losses.

Current Carrying: They handle high current levels and serve as conductors that maintain electrical integrity even under heavy load conditions.

Fault Withstanding: In the event of a short circuit or overload, properly rated busbars can endure high fault currents for a defined period without immediate damage, giving protective devices time to react.

Connection Point: Busbars act as common junctions for electrical components like breakers, fuses, or switches. This simplifies layout and ensures a neat, accessible structure within switchgear or distribution panels.

Voltage Equalization: By offering low impedance, busbars help maintain consistent voltage levels across connected components, reducing the risk of imbalances or equipment stress.

Components & Construction of a Busbar System

A busbar system may appear straightforward at first glance, but its construction is a carefully engineered combination of materials, layers, and insulation that ensures optimal electrical performance and safety.

Conductive Material (Core Bar): The primary component is the conductor, made of copper or aluminum due to their excellent electrical conductivity. Copper is preferred for high-performance applications, while aluminum offers a lighter, cost-effective alternative.

Insulation Layer: Most modern busbars, particularly in compact or high-voltage systems, are covered with an insulating jacket made from materials such as PVC, epoxy resin, or silicone rubber. This layer prevents accidental contact, minimizes arc risk, and allows reduced clearance spacing.

Support Insulators: Non-conductive supports, also known as busbar insulators, secure the bars in place and maintain the spacing between conductive parts. These components are often made from high-strength thermoplastics or porcelain.

Mounting Hardware: Brackets, clamps, and bolts securely hold the busbar in place within switchboards, control panels, or distribution cabinets. These accessories must also be non-magnetic and corrosion-resistant for long-term reliability.

Protective Enclosures: Busbars are often housed in metallic or thermoplastic enclosures, especially in industrial or outdoor environments, to guard against dust, moisture, and mechanical damage.

The construction of a busbar system strikes a balance between performance and safety. Layers are typically laminated or assembled to minimize inductance, reduce electrical noise, and manage thermal output. By integrating these components precisely, busbar systems can handle high current loads while occupying far less space than traditional wiring.

LS Electric America Inc. offers a variety of molded case circuit breakers, surge protective devices, and miniature circuit breakers that integrate seamlessly with busbar systems, enhancing safety and operational reliability.

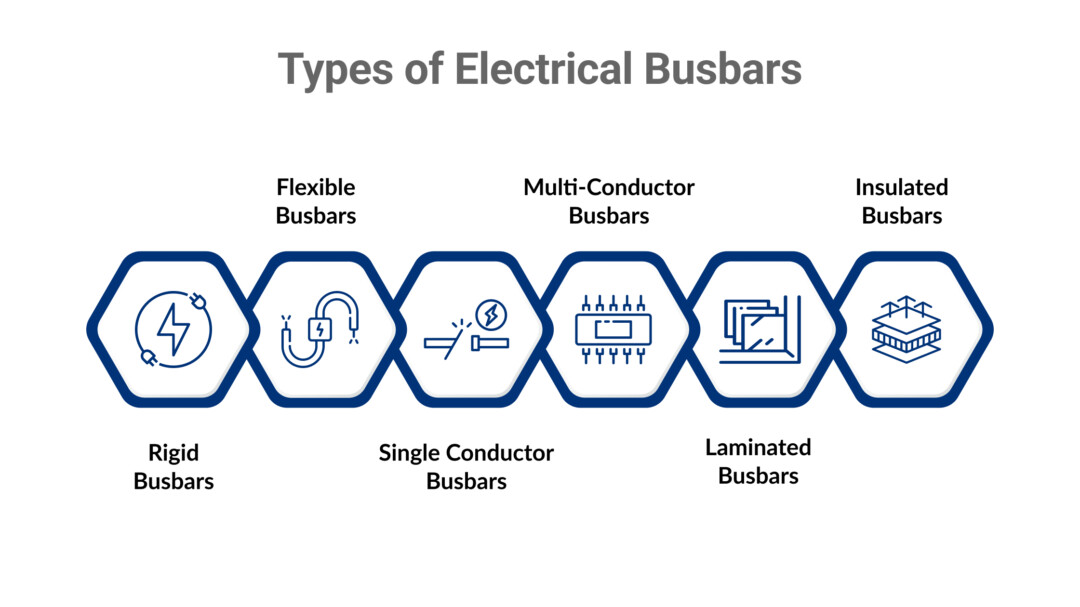

Types of Electrical Busbars

Busbars are available in a range of designs to meet the unique requirements of various electrical environments. From rigid and compact layouts to flexible and layered configurations, each type offers specific advantages in terms of space, performance, and safety.

Choosing the correct type of busbar depends on factors like current load, available space, installation environment, and system flexibility. Below are the most common types used across industries.

Rigid Busbars

Rigid busbars are the most conventional and widely used type in low and medium-voltage systems. They’re constructed from solid copper or aluminum and maintain a fixed shape, usually flat, rectangular bars. Known for their durability and high current-carrying capacity, rigid busbars are ideal for industrial switchgear, control panels, and substations.

Their stiff form enables secure mounting and low-resistance connections, but limits their flexibility during installation. While they offer excellent thermal and electrical performance, rigid busbars require precise planning during layout and may need additional space due to their lack of bendability. These are often used in power distribution systems where layout constraints are minimal and long-term stability is essential.

Flexible Busbars

Flexible busbars are made from stacked or braided strips of copper or aluminum, often wrapped in insulating sleeves. They can bend and twist, making them perfect for tight spaces, movable joints, or environments subject to vibration.

Their adaptability reduces mechanical stress on terminals and improves connection stability. While they may have a slightly lower current capacity than rigid counterparts, flexible busbars allow for faster, easier installations, especially in custom or space-restricted applications.

They’re commonly used in renewable energy systems, electric vehicle setups, and industrial machinery where dynamic movement or space-saving is critical. Their pliability also helps minimize fatigue on electrical joints caused by thermal cycling.

Single Conductor Busbars

As the name suggests, single-conductor busbars consist of a single solid conductor, typically made of flat copper or aluminum. These are favored for their simplicity and excellent current-handling characteristics.

Without insulation or added layers, they provide minimal resistance and effective heat dissipation, making them reliable in high-load environments. They’re often used in power distribution cabinets, transformers, and switchboards. However, due to their open design, they require greater clearance and safety measures to avoid accidental contact or arcing.

Single-conductor busbars are ideal for applications where design simplicity, efficiency, and durability are more important than space optimization or modular flexibility.

Multi-Conductor Busbars

Multi-conductor busbars consist of multiple layers of conductive material, each separated by insulation. These layers are stacked or laminated to carry different circuits within a single, compact unit. This structure offers several advantages, such as reduced wiring complexity, enhanced system organization, and minimal electromagnetic interference.

They are commonly found in control panels, UPS systems, and telecommunications equipment, where space is limited and power distribution is dense. While multi-conductor busbars may cost more upfront due to their design complexity, they significantly reduce installation time and increase system reliability by minimizing loose wiring and connection points. They’re ideal for dense electrical environments requiring clean layouts.

Laminated Busbars

Laminated busbars are advanced, multi-layered assemblies in which copper or aluminum conductors are separated by insulating layers and bonded together under heat and pressure. This compact, flat structure minimizes inductance, allowing for rapid and low-noise power transfer. Laminated busbars are especially useful in high-frequency or high-power-density applications such as inverters, battery banks, and power electronics.

They reduce voltage drop and enhance heat dissipation, making them more efficient than traditional wiring in compact systems. Though they are costlier and more complex to manufacture, their performance advantages in thermal management, electrical reliability, and EMI suppression make them indispensable in modern electrical design.

Insulated Busbars

Insulated busbars feature a solid copper or aluminum conductor encased in a protective layer of insulation. This makes them exceptionally safe for open environments or locations with high human interaction.

The insulation prevents accidental contact, reduces arc flash risk, and enables tighter clearances within panels or switchboards. These busbars are often used in commercial buildings, EV chargers, and modular electrical systems where safety and compact design are essential.

While the insulation may slightly affect heat dissipation, modern materials compensate for this with good thermal conductivity. Insulated busbars offer a balance of safety, space efficiency, and ease of installation.

Applications of Electrical Busbars

Electrical busbars serve as critical components across a wide array of industries, supporting the efficient and safe distribution of power in countless systems. Their ability to handle large currents, reduce wiring complexity, and improve overall reliability makes them indispensable in modern electrical infrastructure.

Here are some of the major applications where electrical busbars play a vital role:

Data Centers: Busbars efficiently distribute high currents to servers and networking equipment, enabling compact and reliable power management.

Renewable Energy Systems: Used in solar farms and wind turbines to collect and distribute generated power safely and effectively.

Electric Vehicles (EVs) and Charging Stations: Facilitate high-current flow for battery packs and rapid charging infrastructure.

Industrial Control Panels: Simplify wiring and improve power distribution reliability in manufacturing and automation setups.

Power Distribution Units (PDUs): Provide organized and scalable power routing in commercial and industrial environments.

Residential and Commercial Buildings: Used in switchboards and main distribution panels for safe and efficient electrical distribution.

Electrical Switchgear and Substations: Critical for connecting high-power circuits with minimal losses and high durability.

Manufacturing Facilities: Support heavy machinery and process equipment with stable and low-resistance power pathways.

Marine Applications: Provide electrical distribution on ships and offshore platforms, resisting corrosion and vibration.

Rail Systems and Infrastructure: Ensure a reliable power supply for trains, signaling systems, and stations.

Aerospace and Defense Systems: Deliver compact, reliable power in high-demand, space-constrained applications.

Telecommunication Infrastructure: Maintain clean, stable power for sensitive communication equipment.

Medical Equipment and Facilities: Guarantee uninterrupted power for critical medical devices and systems.

Robotics and Automation Systems: Support dynamic and high-current power demands in automated production lines.

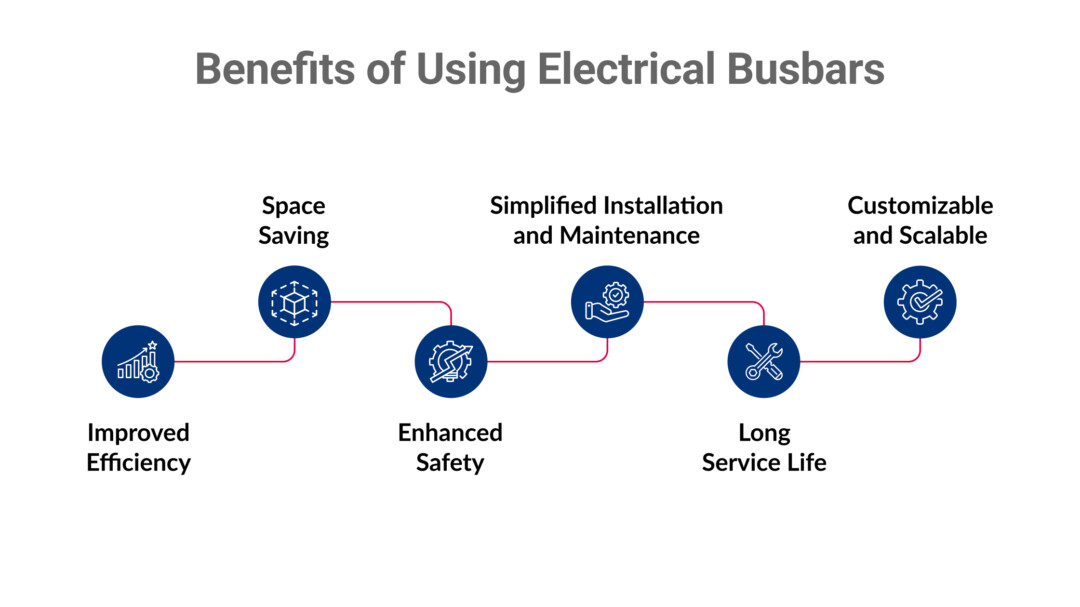

Benefits of Using Electrical Busbars

Below are the core advantages that make them a go-to choice in modern power distribution systems.

Improved Efficiency

Electrical busbars offer a low-resistance path for current flow, significantly reducing energy loss compared to traditional cabling. This enhanced efficiency lowers electricity costs and also supports more stable and reliable power distribution, which is crucial for high-demand environments.

Space Saving

By consolidating multiple connections into a single conductor, busbars enable more compact and organized setups. This is especially valuable in control panels and switchgear, where space is at a premium and a clean layout improves both function and accessibility.

Enhanced Safety

Busbars reduce the amount of exposed wiring, minimizing the risk of short circuits, loose connections, and electrical faults. Their enclosed and structured design enhances overall system safety and reduces the likelihood of human error during installation or maintenance.

Simplified Installation and Maintenance

Compared to complex cable arrangements, busbars are easier to install and maintain. With fewer components and better accessibility, technicians can perform inspections, upgrades, or repairs more efficiently, saving time and reducing operational downtime.

Long Service Life

Built to withstand mechanical and thermal stress, busbars are renowned for their exceptional durability. Their solid construction ensures consistent performance over time, resulting in fewer failures and lower maintenance costs throughout the system’s lifecycle.

Customizable and Scalable

With various types available, such as rigid, flexible, and laminated, busbars can be tailored to fit specific operational needs. This flexibility allows systems to scale or adapt without major overhauls, enhancing long-term reliability and design efficiency.

Get Expert Support for Your Busbar and Power Needs from LS Electric America Inc.

Electrical busbars are essential components that enhance the efficiency, safety, and reliability of power distribution systems across industries. Selecting the correct busbar type and ensuring proper installation and maintenance can significantly improve system performance and minimize downtime.

At LS Electric America Inc., we offer a comprehensive range of high-quality electrical solutions tailored to meet your specific power distribution requirements. Our products, including low-voltage switchgear, molded case circuit breakers, surge protective devices, and soft starters, deliver reliable performance and superior protection for your systems.

Explore LS Electric’s Product Range

- Molded Case Circuit Breakers

- Miniature Circuit Breakers

- Surge Protective Devices

- Contactors & Overload Relays

- Electronic Motor Protection Relays

- Soft Starters

Power your operations safely and efficiently. Discover how our advanced solutions can optimize your electrical systems, ensuring your business operates smoothly.