Unexpected downtime is one of the most expensive problems facing industrial operations today, with unplanned outages costing manufacturers an estimated $50 billion annually. At the center of many of these disruptions are industrial control panels, complex systems that regulate, monitor, and automate machinery across nearly every sector of the economy.

When these panels fail, the consequences ripple across entire production lines. Faulty wiring, power supply fluctuations, or a single failed component can grind operations to a halt. That’s why fast, informed troubleshooting is a business imperative.

In this blog, we’ll walk through the most common issues found in industrial control panels, practical methods to diagnose them, and proactive steps you can take to avoid recurring failures. Whether you’re maintaining an aging system or responding to a sudden fault, these strategies will help you minimise downtime and protect your equipment.

Understanding the Industrial Control Panel Ecosystem

Industrial control panels are the operational core of modern industrial systems. These panels house a coordinated network of electrical devices that monitor, manage, and automate machinery across facilities. Understanding how this ecosystem functions is the first step toward diagnosing problems when they arise.

At their most basic, control panels include:

- Power distribution components (like breakers and transformers)

- Control devices (such as relays, timers, and PLCs)

- Operator interfaces (HMIs or switches)

- Safety systems (emergency stops, circuit protection, etc.).

These components are integrated to regulate machine functions, ensure safety, and enable precise control in real-time.

In high-stakes environments, such as manufacturing, water treatment, or mining, even a brief disruption to one part of the system can throw off entire processes. What makes troubleshooting challenging is that failures often involve multiple components or environmental stressors, not just a single faulty wire or relay.

By viewing the control panel as a comprehensive ecosystem comprising electrical, mechanical, and digital elements that work together, you gain a broader diagnostic lens. This perspective is essential not just for solving problems, but also for implementing proactive maintenance and long-term reliability strategies.

Common Control Panel Issues & Troubleshooting Methods

Even the most well-designed industrial control panels are not immune to failure. With dozens of interconnected components running in high-demand environments, it’s no surprise that issues can and do occur. These faults can lead to machine downtime, safety risks, or compromised system performance, especially if they aren’t identified and resolved quickly.

However, most of the control panel problems stem from a handful of recurring causes. By recognizing these common issues early and applying structured control panel troubleshooting tips, operators can minimize downtime and avoid expensive repairs.

1. Component Failures

Component failure is one of the most common and disruptive issues in industrial control panels. These panels are constructed with numerous active and passive components, including relays, contactors, timers, PLCs, switches, and sensors. Over time, these parts can degrade due to wear, electrical fatigue, mechanical stress, or simply end-of-life failure.

A malfunctioning component can lead to anything from delayed operations to complete system shutdown.

For example, a failed contactor might prevent a motor from starting, while a faulty relay could result in unpredictable switching behavior. The consequences often extend beyond the component itself, affecting downstream systems or creating unsafe operating conditions. You need the right control panel troubleshooting tips to make it work.

Troubleshooting Approach:

Visual Inspection: Check for burn marks, corrosion, loose connections, or signs of overheating. Swollen capacitors or discoloured components often indicate failure.

Functionality Testing: Use a multimeter or continuity tester to verify the presence of open or short circuits in relays, fuses, or coils.

Diagnostics Tools: Many PLCs and smart relays offer built-in diagnostic LEDs or error codes. Cross-reference these with the manufacturer’s documentation to pinpoint the fault.

Replacement Strategy: Always use manufacturer-approved components to maintain safety certifications and compatibility. If a critical part is failing repeatedly, review the load sizing or consider upgrading to a higher-spec component.

Preventive maintenance plays a significant role here. Establishing a regular inspection and testing schedule helps catch deteriorating components before they fail, reducing unplanned downtime and extending equipment life. Utilize an electronic motor protection relay to offer inverse time protection for a range of ratings.

2. Environmental Stress and Panel Contamination

Industrial control panels often operate in challenging environments, ranging from hot manufacturing floors and dusty warehouses to humid processing plants. These harsh conditions can take a toll on sensitive electronic components inside the panel. Excessive heat, humidity, dust, and corrosive particles are common causes of premature failure or erratic behavior in control equipment.

Elevated temperatures accelerate the aging of semiconductors and insulation, while condensation from high humidity can lead to short circuits and corrosion. Dust accumulation may block vents, causing overheating or reduced airflow, and can even create conductive paths between terminals if left unchecked.

Troubleshooting Approach:

Inspect Ventilation and Cooling: Ensure that fans, filters, and ventilation paths are clear and functioning correctly. Panels in high-temperature zones should have active cooling, like air conditioners or heat exchangers.

Check Sealing and Enclosure Ratings: Enclosures should match the environmental exposure (e.g., IP54 for dust; IP65+ or NEMA 4X for wet or corrosive environments).

Clean Internals: Power down and use anti-static brushes or vacuum cleaners (not compressed air) to remove dust. Inspect for rust or moisture on terminals and PCBs.

Monitor Ambient Conditions: Install temperature and humidity sensors for continuous monitoring. If thresholds are regularly exceeded, consider relocating the panel or improving HVAC systems.

Building in environmental safeguards from the design phase, such as appropriate panel enclosures, climate control, and ingress protection, goes a long way in maintaining system reliability. These control panel troubleshooting tips can prevent slow degradation and avoid major failures.

3. Power Supply Instability

Unstable or inconsistent power supply is another critical issue that can compromise the performance of industrial control panels. Voltage sags, surges, and interruptions can originate from the utility grid, nearby heavy machinery, or even internal faults, each of which is capable of damaging sensitive components such as PLCs, HMIs, and communication modules. In extreme cases, power fluctuations can cause data loss, system resets, or complete operational halts.

Even short-duration voltage drops (brownouts) can be enough to trigger nuisance trips or equipment misbehavior, especially in highly automated processes.

Troubleshooting Approach:

Measure Line Voltage: Use a multimeter or power quality analyzer to verify that the incoming voltage is within the manufacturer’s specified tolerance (typically ±10%).

Inspect Power Entry Points: Look for loose terminal connections, corrosion, or heat discoloration that may indicate arcing or voltage drop at the main feed.

Check Grounding and Bonding: A poor or missing ground can lead to transient voltage buildup, static discharge, and unreliable signal processing.

Review UPS and Surge Protection: Inconsistent power may signal a failing UPS battery, inadequate surge suppression, or an undersized voltage regulator.

To mitigate future risks, consider implementing line conditioners, isolation transformers, or industrial-grade surge protection devices. Monitoring power quality over time, not just during failure, can provide actionable insights that prevent recurring disruptions and extend equipment lifespan.

4. Wiring and Connection Issues

Poor or deteriorating wiring is one of the most overlooked causes of industrial control panel malfunctions. Over time, wires can loosen, corrode, or suffer insulation damage due to vibration, heat, or rodent activity. Even a single loose terminal or nicked cable can result in intermittent signals, false trips, or complete circuit failures, making diagnosis tricky and time-consuming.

Improper wire routing, lack of strain relief, or mixing low- and high-voltage lines can also introduce noise and electromagnetic interference (EMI), disrupting control signals and compromising system reliability.

Troubleshooting Approach:

Visual Inspection: Start by checking all terminals, connectors, and cable paths. Look for signs of discoloration, frayed insulation, or exposed conductors.

Test Continuity and Resistance: Use a multimeter to confirm continuity across key connections and measure resistance to identify corrosion or breaks.

Verify Tightness: Torque-check critical connections using a torque screwdriver or meter, especially after thermal cycling or heavy vibrations.

Organise and Shield Cables: Ensure proper cable segregation between power and signal lines, and use shielded cables with correct grounding practices to reduce EMI.

Routine wire management, including labeling, bundling, and scheduled retightening, can significantly reduce troubleshooting time and improve long-term system reliability.

5. Overloading and Excessive Current Draw

One of the most common causes of sudden control panel failure is electrical overloading. This occurs when the current flowing through a circuit exceeds its design limits, usually due to plugging in too many devices, using equipment that draws high current, or a short circuit somewhere in the system. Over time, even minor overloads can lead to overheated conductors, damaged circuit breakers, and ultimately, a system shutdown.

Beyond damaging components, overloads can create serious safety risks, including fire hazards or cascading failures that affect upstream electrical systems.

Troubleshooting Approach:

Inspect Tripped Breakers or Fuses: Frequent tripping indicates consistent overcurrent. Resetting isn’t enough. Identify what’s causing the overload before re-energising.

Check Load Ratings: Use a clamp meter to measure actual current draw and compare it with rated values for the breaker, wire gauge, and equipment.

Balance Loads: Uneven distribution of loads across phases can lead to imbalance and overload on one leg. Rebalancing may prevent repeated failures.

Isolate and Test Equipment: Disconnect loads and reintroduce them one by one to identify any equipment drawing abnormal current.

Preventing overloading begins with proper design, including correctly sizing circuit breakers, cables, and busbars, and ensuring that expansions or retrofits don’t exceed capacity. A panel designed for 100A service can’t safely support 120A, even if things “seem to run fine” in the short term. Continuous monitoring with current sensors or contactors & overload relays can also help preempt overload risks before they escalate.

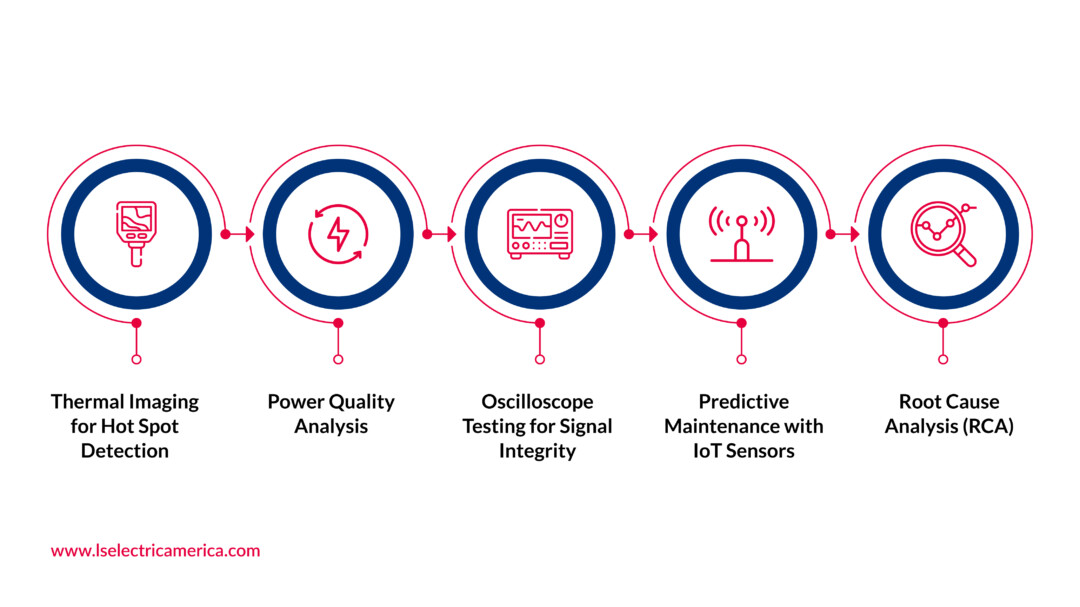

Advanced Troubleshooting Control Panel Troubleshooting Tips

When standard troubleshooting methods fail to resolve issues, advanced control panel troubleshooting tips can help identify underlying problems within your industrial control panels. Here are some expert-recommended approaches to enhance your diagnostic process:

Thermal Imaging for Hot Spot Detection

Using thermal cameras allows you to identify overheating components, loose connections, or overloaded circuits before they fail. Detecting these hot spots early can prevent unexpected downtime and costly repairs.

Power Quality Analysis

Monitoring voltage levels, sags, surges, and harmonic distortions with power quality analyzers can reveal electrical disturbances that impact control panel performance. Understanding these factors helps maintain system stability and protects sensitive equipment.

Oscilloscope Testing for Signal Integrity

Oscilloscopes provide real-time visualization of electrical signals within control circuits, enabling the detection of noise, spikes, or timing issues. This is particularly useful for verifying PLC inputs and outputs, and ensuring reliable communication in complex systems.

Predictive Maintenance with IoT Sensors

Integrating IoT sensors and predictive maintenance software enables continuous monitoring of equipment health. This proactive approach can flag potential failures early, reducing unplanned downtime and lowering maintenance costs.

Root Cause Analysis (RCA)

Employing systematic techniques, such as the “5 Whys” or Fishbone Diagrams, helps identify the underlying causes of recurring issues. Addressing root causes improves overall reliability and prevents future control panel problems.

By incorporating these advanced troubleshooting strategies, you can improve the longevity, safety, and performance of your industrial control panels while minimizing operational disruptions.

Best Practices to Prevent Recurring Industrial Control Panel Issues

Preventing problems before they arise is key to maintaining reliable industrial control panels. Implementing these best practices can significantly reduce downtime and extend the life of your control systems:

Regular Inspection and Preventive Maintenance

Schedule routine checks to inspect components for wear, corrosion, or damage. Clean panels periodically to remove dust and debris, and verify the tightness of wiring and connections. Preventive maintenance helps catch issues early, avoiding unexpected failures.

Proper Environmental Protection

Ensure that control panels are housed in enclosures suitable for their operating environment. Use sealed, dustproof, and ventilated enclosures where needed to guard against moisture, temperature extremes, and contaminants.

Correct Component Sizing and Ratings

Use components rated appropriately for the electrical loads and environmental conditions. Oversized or undersized parts can lead to premature failures or inefficiency.

Accurate Wiring and Documentation

Follow industry standards for wiring and labeling. Maintain up-to-date wiring diagrams and documentation to simplify troubleshooting and future upgrades.

Implement Surge Protection and Grounding

Protect control panels from voltage spikes and electrical noise with surge protectors and ensure proper grounding. This reduces damage from power disturbances and improves system stability.

Training and Safety Protocols

Ensure technicians and operators are trained in safe handling, operation, and troubleshooting of control panels. Clear procedures and safety protocols prevent human error-related issues.

Optimize Your Control Panels with Trusted LSElectric America Inc. Products

Industrial control panels ensure that industrial operations run smoothly, preventing costly downtime and maintaining productivity. By understanding common issues and applying effective control panel troubleshooting tips, you can ensure your control panels deliver reliable performance day after day.

When it comes to dependable industrial control solutions, LSElectric America Inc. stands out with a broad range of products tailored to meet your needs, including:

- Contactors & Overload Relays to safeguard motors from electrical faults

- Electronic Motor Protection Relays for precise monitoring and fault detection

- Manual Motor Starters for simple, reliable motor activation

- Miniature and Molded Case Circuit Breakers to protect circuits from overload and short circuits

- Surge Protective Devices that shield equipment from voltage spikes

- Soft Starters to ensure smooth motor startup and reduce mechanical stress

Whether you’re looking to upgrade or maintain your control panels, LSElectric’s products combine durability, innovation, and ease of integration to minimize downtime and maximize productivity.

Learn how our solutions can enhance your industrial control systems and protect your critical operations.