As modern power systems become more automated and complex, relays, though small, play a vital role in ensuring functionality, protection, and control. But what exactly is a relay in electrical engineering?

The global protective relay market is expected to reach USD 6.5 billion by 2027, growing at a CAGR of 5.2%. This surge reflects the growing need for reliable electrical protection and automated systems in industrial, utility, and commercial sectors.

In this blog, we’ll discuss what an electrical relay is, how it works, the different types of relays, their symbols, wiring diagrams, and typical real-world applications.

What is a Relay?

A relay is an electrically operated switch that controls circuits in various electronic and electrical systems. Unlike manual switches, which require human interaction to open or close a circuit, relays function automatically in response to an electrical signal. When a small input signal is applied to the relay’s coil, it generates a magnetic field that moves internal contacts, either completing or interrupting the circuit connected to a separate, usually higher-power load.

The concept is similar to a baton pass in a relay race. One component receives the signal and passes it along to another. This allows a low-voltage control circuit to safely and efficiently manage much larger voltages or currents without direct electrical contact. Relays are critical when electrical isolation, remote control, or automatic switching are required.

Relays are essential to modern automation and safety systems, whether turning on a motor, activating headlights, or managing power flow in a substation. Their design allows for precise control, quick switching, and reliable operation, making them crucial in industrial power grids.

How Does an Electrical Relay Work?

An electrical relay operates as an electromechanical switch that uses a small input signal to control a much larger electrical load. The relay’s design isolates control circuitry from high-power circuits, ensuring safety and automation. Here’s a breakdown of its working components and steps:

Major Components of a Relay

- Electromagnet (Coil): This is the heart of the relay. When electrical current passes through the coil, it creates a magnetic field.

- Movable Armature: Positioned near the coil, this metal lever is pulled toward the coil when magnetized.

- Contacts (Normally Open or Normally Closed): These are the points that open or close to either allow or block current in the output circuit.

- Spring: This returns the armature to its original position when the coil is de-energized.

These parts work together to ensure precise switching. For advanced and compact protection, LS Electric offers the DMPi Intelligent Digital Motor Protection Relay, which integrates control and diagnostic features.

Steps in Relay Operation:

- Input Signal: A low-voltage electrical signal (e.g., from a sensor or microcontroller) is sent to the relay’s coil.

- Magnetic Field Generation: The coil energizes, generating a magnetic field.

- Armature Movement: The magnetic field pulls the armature toward the coil. This action either closes a normally open or a normally closed contact.

- Circuit Control: The movement of the contacts completes or interrupts the external high-power circuit. This allows the connected device, such as a motor, fan, or light, to be powered on or off.

- Reset: Once the input signal is removed, the coil is de-energized, the magnetic field disappears, and the spring pulls the armature back, resetting the relay to its default state.

This sequence enables a low-power control circuit to safely and reliably control a high-power load, which is essential in automation, safety systems, and remote operations.

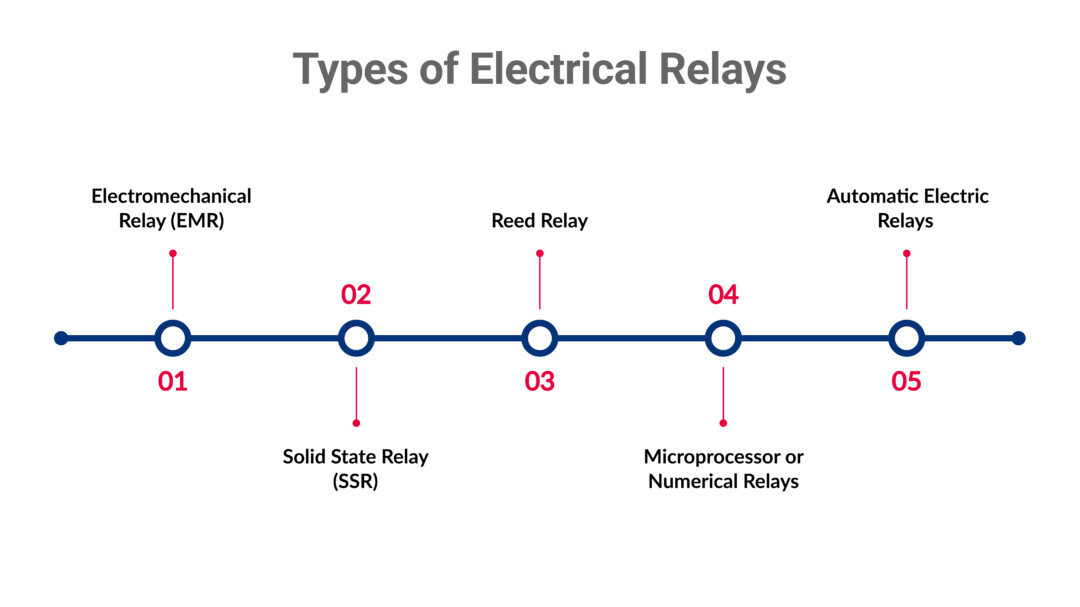

Types of Electrical Relays

Several types of relays are used in electrical systems. Each has a specific function based on current, voltage, timing, or application requirements.

-

Electromechanical Relay (EMR)

An electromechanical relay uses a magnetic coil to physically open or close contacts, creating or interrupting a circuit. These relays are known for their reliability, easy troubleshooting, and versatility in handling AC and DC loads. They’re widely used in automation, home appliances, and HVAC systems, though mechanical wear can limit lifespan.

Features:

- Audible click when switching

- Capable of switching AC and DC loads

- Easy to troubleshoot and replace

Applications:

- Industrial automation

- Home appliances

- HVAC systems

-

Solid State Relay (SSR)

A solid-state relay uses semiconductor components like thyristors or triacs to switch without moving parts. This design allows faster, quieter, and more durable operation than conventional relays. SSRs are ideal for applications involving microcontrollers, sensitive electronics, or high-speed switching tasks, though they may require heat sinks due to thermal buildup.

Features:

- Silent operation

- No mechanical wear

- Fast switching

- High reliability

Applications:

- Sensitive equipment

- High-speed control circuits

- Electronics and microprocessor interfaces

-

Reed Relay

A reed relay contains two magnetic metal reeds sealed inside a glass tube. When the coil is energized, the reeds attract each other and complete the circuit. These relays are compact, fast-switching, and highly durable, making them suitable for telecommunications, medical equipment, test systems, and circuits requiring low power and high reliability.

Features:

- Very fast switching

- Long operational life

- Compact size

Applications:

- Telecommunication

- Test equipment

- Safety circuits

-

Microprocessor or Numerical Relays

Microprocessors or numerical relays are advanced devices used in protection and control systems. They utilize embedded systems and digital processing to monitor electrical parameters, detect faults, and provide real-time protection. These relays are programmed to perform complex logic functions, offering greater precision and flexibility in protecting electrical systems.

Features:

- Advanced Protection Algorithms

- Digital Signal Processing.

- Flexibility and Customization

- Communication Capabilities

Applications:

- Motor Protection

- Power Systems

- Automation Systems

- Renewable Energy Systems

- Smart Grids

-

Automatic Electric Relays

Automatic relays perform switching operations without manual intervention. They monitor system parameters and trigger protective or control functions based on preset conditions.

The automation relay segment is essential for innovative grid modernization. Automatic electric relays enable fast fault detection and reduce downtime in high-demand environments like data centers and renewable energy systems.

These relays are often integrated with:

- SCADA systems

- Programmable Logic Controllers (PLCs)

- Remote monitoring systems

Automatic electric relays enhance efficiency and safety by enabling responsive, hands-free control in complex electrical systems. Integrated with SCADA, PLCs, and remote monitoring tools, they play a vital role in modern energy infrastructure, especially in smart grids, data centers, and renewable systems, by ensuring fast fault detection and minimizing operational disruptions.

Applications of Electrical Relays

Relays are widely used in residential, commercial, industrial, and automotive sectors. Their versatility and reliability make them indispensable in modern electrical systems.

Industrial Vehicle Control Systems

Relays are essential in controlling electrical systems within industrial vehicles such as forklifts, cranes, mining trucks, and construction machinery. These vehicles often require high-current switching for components like hydraulic pumps, lighting systems, and cooling fans.

Relays use low-voltage control signals to enable the reliable and safe operation of these high-demand systems in rugged environments. This helps protect control circuits from electrical surges while supporting automation, remote diagnostics, and system uptime in industrial fleet operations.

Industrial Process Controllers

In industrial automation, relays control motors, pumps, and conveyor belts. They enable safe switching and circuit isolation, which are vital in managing complex workflows, improving productivity, and reducing system failures due to overloads or faults.

Power System Protection

Electrical relays act as protective devices in power transmission and distribution systems. They detect faults like overcurrent, under-voltage, or short circuits, and trigger circuit breakers to prevent damage to transformers, feeders, and connected equipment.

Lighting Control Systems

Relays are widely used in commercial and industrial lighting systems, such as factories, warehouses, and smart buildings. They integrate with occupancy sensors, building management systems (BMS), or programmable controllers to enable automated control, scheduled switching, and energy efficiency. This automation improves operational efficiency, reduces energy costs, and enhances workplace safety in large-scale lighting installations.

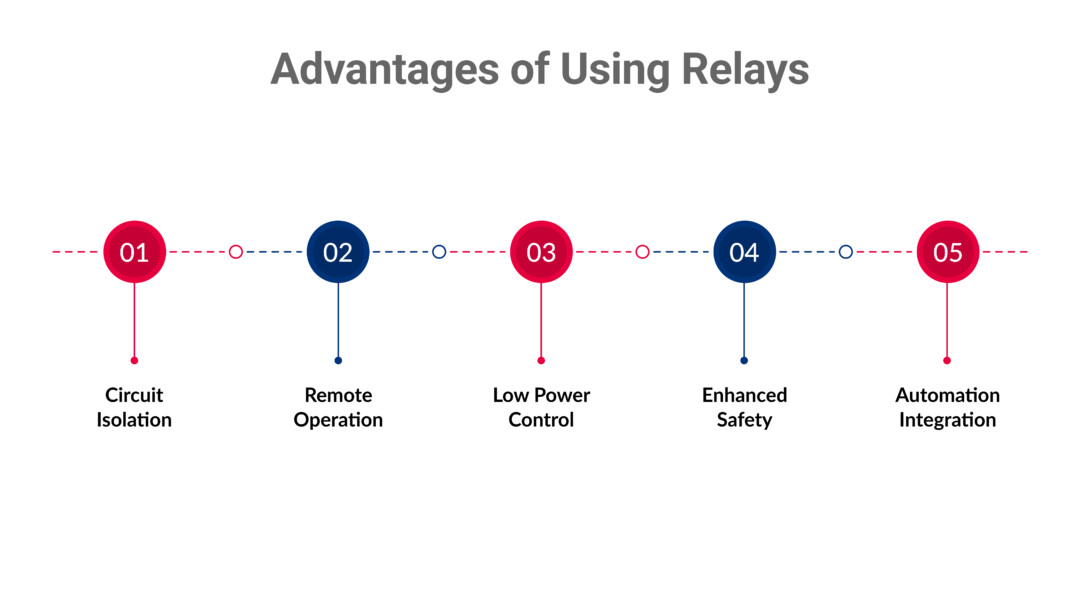

Advantages of Using Relays

Relays play a crucial role in both simple and complex electrical systems. Their ability to control high-power circuits with low-power signals offers several advantages in safety, efficiency, and reliability.

Circuit Isolation

Relays electrically isolate the control circuit from the load circuit, protecting sensitive components from voltage spikes, noise, or overloads, ensuring the control side remains safe and operational.

Remote Operation

Relays allow circuits to be operated remotely, making them ideal for automation systems, where switches or sensors control devices at a distance without requiring direct wiring.

Low Power Control

A low-power input signal can switch high-current loads with relays, enabling efficient control in devices like automotive systems, home appliances, and industrial equipment.

Enhanced Safety

By instantly disconnecting faulty circuits, relays minimize fire hazards, equipment damage, or electric shock risks, contributing to the safer operation of electrical systems in homes, vehicles, and industries.

Automation Integration

Relays are compatible with programmable logic controllers (PLCs) and intelligent systems, making them a core component in industrial automation and smart grid technologies for optimized energy management.

Things to Consider When Selecting an Electrical Relay

Voltage and Current Ratings

Ensure the relay’s ratings align with your system’s input and load requirements. Incorrect ratings can lead to malfunction or damage, especially in high-demand circuits or variable power environments.

Type of Load

Inductive and resistive loads behave differently under switching. Choose relays with suitable arc suppression or durability features depending on whether you’re controlling motors, heaters, or other load types.

Response Time

For fast-switching applications, use relays with minimal delay, such as SSRs or reed types. This ensures accurate control in time-sensitive systems like automation, safety circuits, or signal processing.

Environmental Conditions

Harsh conditions require sealed or solid-state relays that resist moisture, dust, and temperature fluctuations. Always consider the operating environment to avoid premature failure or safety issues.

Mounting Style

Relay mounting options—such as DIN rail, PCB, or plug-in—affect installation, maintenance, and space usage. Choose based on your panel layout, accessibility needs, and system scalability.

Certifications

Look for UL, CE, or IEC certifications to ensure regional and industry standards compliance. Certified relays meet required safety and performance benchmarks for commercial and industrial use.

Optimize Your Industrial Control Systems with LS Electric America Inc.

Whether you’re overseeing facility upgrades, specifying components for new builds, or standardizing control systems across sites, choosing the right relay is critical to performance and reliability.

LS Electric America’s industrial-grade relay solutions are engineered for precision, durability, and seamless integration across complex environments, from manufacturing plants to smart energy infrastructure.

- UL, CE, and IEC certified for compliance and peace of mind

- Built for heavy-duty industrial applications

- Backed by expert engineering support

Streamline procurement, simplify integration, and maximize uptime by exploring our full product line or consulting with a relay specialist today.