Meta description – Learn what a protective relay is, its importance, working, and types in modern electrical systems.

A Complete Guide to Protective Relays and Their Role in Power Systems

Power interruptions drain an estimated $150 billion annually from the U.S. economy, and many of these costly losses start with a fault that lasts less than a second. In that brief moment, equipment can fail, production can halt, and safety can be compromised.

But the shocking thing is that most of these incidents could be avoided with faster fault detection and isolation. Without it, a minor electrical issue can snowball into a system-wide outage or dangerous event.

Protective relaying aims to stop that chain reaction before it starts, detecting problems instantly, cutting off the affected section, and keeping the rest of the system stable and safe.

In this blog, we’ll discuss the essentials of protective relaying, exploring how it helps maintain system integrity, protects valuable equipment, and reduces costly downtime.

What is a Protective Relay?

| A protective relay is an intelligent device that senses abnormal electrical conditions, such as overcurrent, under-voltage, or frequency deviations. It initiates the operation of circuit breakers to isolate the affected section. This prevents damage to equipment, reduces downtime, and safeguards human life. |

Primary Functions of a Protective Relay

- Fault Detection: Identifies abnormal operating conditions before significant damage occurs.

- Trip Initiation: Sends a precise command to circuit breakers for immediate fault isolation.

- Fault Duration Reduction: Minimizes the time faults remain in the system, limiting damage.

- System Monitoring: Records and communicates electrical parameters for analysis and preventive action.

Importance of a Protective Relay

- Safety: Prevents hazards such as fires, arc flashes, and electrocution by removing dangerous faults rapidly.

- Equipment Protection: Preserves transformers, generators, motors, and other critical assets from fault damage.

- Operational Continuity: Restricts outages to affected areas, keeping the rest of the system online.

- System Stability: Maintains voltage, frequency, and power quality to avoid cascading failures.

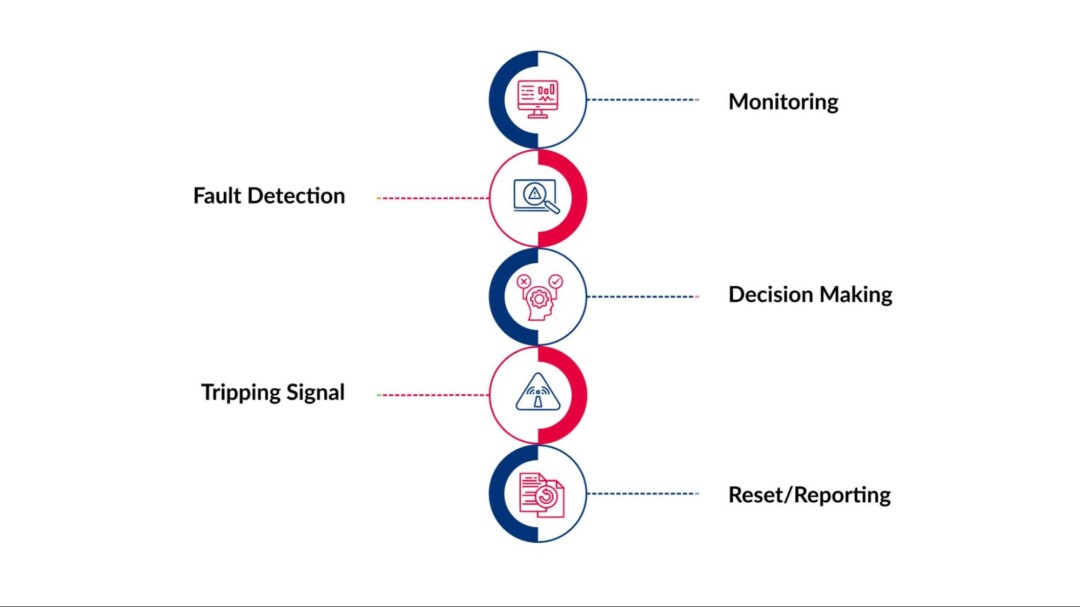

How Does a Protective Relay Work?

A protective relay operates by continuously monitoring electrical parameters, detecting abnormalities, making decisions, and triggering circuit breakers to isolate faulty sections. This process helps protect equipment, maintain power system stability, and ensure safety for personnel and operations.

-

Monitoring

The relay measures voltage, current, frequency, and other parameters using Current Transformers (CTs) and Voltage Transformers (VTs). These inputs provide accurate real-time data for assessing system health and identifying potential fault conditions before they escalate.

-

Fault Detection

The device compares real-time measurements with predefined thresholds or settings. If a parameter exceeds the safe limit, the relay instantly flags the event as an abnormal condition, ensuring that no unsafe electrical situation goes unnoticed.

-

Decision Making

Once an abnormality is detected, the relay’s logic system decides whether isolation is necessary. It considers factors such as fault severity, type, and location to prevent unnecessary trips while ensuring timely protection when conditions demand action.

-

Tripping Signal

If isolation is required, the relay sends a rapid signal to the associated circuit breaker. The breaker then disconnects the faulty section from the network, preventing damage to equipment and minimizing the impact on unaffected areas.

-

Reset/Reporting

After the fault is cleared, the relay logs all event details for analysis. Depending on the design, it may reset automatically or require manual intervention, ensuring preparedness for future fault detection and continuous system protection.

Types of Protective Relays

Protective relays work in conjunction with various electrical protection and control devices, such as Miniature Circuit Breakers (MCBs) and Molded Case Circuit Breakers (MCCBs), to maintain system stability and prevent damage during fault conditions.

-

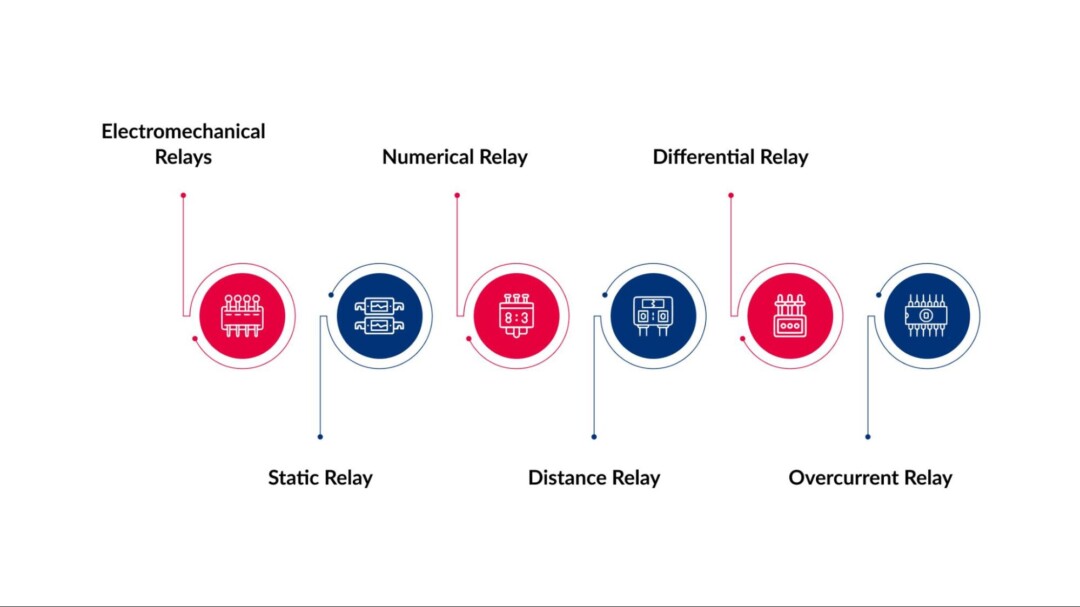

Electromechanical Relays

These conventional relays operate using magnetic induction or attraction to physically move components such as arms, contacts, and springs. When a fault occurs, the change in electrical conditions generates a magnetic force that triggers mechanical movement, opening or closing contacts to trip the circuit breaker.

They are valued for their ruggedness and ability to handle harsh operating environments, but require periodic calibration and maintenance due to moving parts.

Common Applications: Used in legacy power systems, older industrial facilities, and utility substations where equipment has not yet been upgraded to electronic or microprocessor-based designs.

-

Static Relay

Static relays use solid-state components, such as transistors, diodes, and operational amplifiers, to perform fault detection without moving parts. They process the electrical signal electronically, which increases speed, accuracy, and reliability.

The absence of mechanical wear makes them low-maintenance, and they are less prone to environmental damage from vibration or dust compared to electromechanical relays.

Common Applications: Widely applied in medium-voltage distribution systems, industrial automation, and environments requiring high-speed protection with minimal servicing.

-

Numerical Relay

These advanced relays are microprocessor-based and capable of performing multiple protective, control, and monitoring functions in a single device. They analyze system parameters using digital algorithms, provide event recording, run self-diagnostics, and can communicate with SCADA and other supervisory systems.

Their programmability allows settings to be adjusted for different protection zones, and they can integrate seamlessly with other digital protection schemes.

Common Applications: Modern power grids, renewable energy facilities, smart substations, and integrated network protection, where multifunction capability and real-time data exchange are essential.

-

Distance Relay

Distance relays detect faults by measuring the impedance between the relay location and the fault point, which is proportional to the distance along the conductor. When the measured impedance falls below a preset value, the relay assumes the fault lies within its protection zone and issues a trip command.

They are particularly effective in long-line protection because they are less affected by load currents than overcurrent relays.

Common Applications: High-voltage transmission line protection, long feeder circuits, and selective tripping in large interconnected networks.

-

Differential Relay

These relays operate on the principle of comparing the current entering and leaving a specific protection zone, such as a transformer winding, generator stator, or busbar section. Any difference between the two indicates an internal fault, triggering an immediate trip.

This high-speed and highly selective protection method ensures internal faults are cleared rapidly while external disturbances are ignored.

Common Applications: Transformer protection, generator winding protection, large motor circuits, and busbar fault isolation.

-

Overcurrent Relay

An overcurrent relay operates when the current in a circuit exceeds a preset value for a specified period. It can be configured for instantaneous operation to trip immediately during severe faults, or for time-delayed operation to allow temporary current surges, such as motor starting.

Many industrial systems use thermal overload relays, which employ a bimetallic element that bends with heat generated by excessive current. This mechanical movement triggers the trip mechanism, disconnecting the motor or circuit to prevent overheating and potential damage.

Overcurrent relays are simple, dependable, and available in electromechanical, thermal, or electronic designs, making them adaptable to a wide range of protection needs.

Common Applications: Motor and feeder protection, distribution transformers, low- and medium-voltage distribution systems, and backup protection for transmission lines.

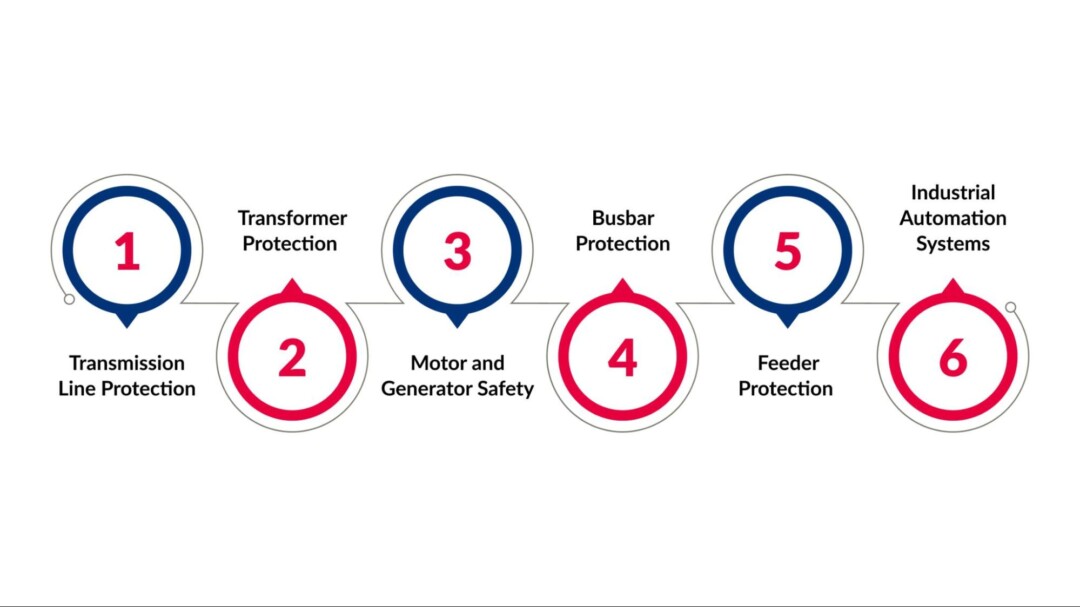

Applications of Protective Relays

Protective relays are essential in power systems to detect faults, isolate problem areas, and prevent widespread damage. Their use spans high-voltage transmission, industrial machinery, and automated systems, ensuring both safety and operational reliability in diverse environments.

-

Transmission Line Protection

Protective relays monitor long-distance high-voltage lines for faults like short circuits or grounding. Quick isolation prevents damage to infrastructure, avoids power loss to large areas, and reduces the risk of cascading failures in the electrical network.

-

Transformer Protection

Relays safeguard transformers from overloads, short circuits, and insulation breakdown. This protection helps prevent costly equipment damage, ensures stable voltage delivery, and prolongs the operational life of transformers in utility and industrial power systems.

-

Motor and Generator Safety

Motors and generators are vulnerable to overcurrent, phase imbalance, and overheating. Protective relays detect these issues early, triggering shutdowns to avoid mechanical damage, production losses, and hazards to surrounding equipment or operating personnel.

-

Busbar Protection

Busbars carry large amounts of current, and faults here can disrupt the entire power system. Relays detect such faults instantly, allowing rapid isolation to protect connected equipment and maintain supply stability across the electrical network.

-

Feeder Protection

Feeders distribute power from substations to load points. Relays detect overloads, short circuits, and earth faults on feeders, ensuring that faults are cleared locally without affecting the rest of the system’s performance or service continuity.

-

Industrial Automation Systems

In automated plants, protective relays integrate with control systems to monitor electrical health continuously. They protect critical machines, minimize downtime, and ensure production processes remain safe and efficient under both normal and fault conditions.

Advantages of Using Protective Relays

Protective relays offer multiple benefits that enhance power system reliability, efficiency, and safety.

-

Rapid Fault Detection

Protective relays respond within milliseconds, identifying faults before they spread or cause extensive damage. This fast reaction minimizes the impact on equipment and operations, ensuring safety for personnel while reducing the likelihood of large-scale blackouts or prolonged downtime in power systems.

-

Automation Capability

Once configured, protective relays work automatically without requiring manual monitoring. This automation allows faults to be cleared swiftly, avoiding delays that could worsen conditions. It also frees operators to focus on system optimization instead of constant fault supervision.

-

Adaptability

Modern protective relays can be programmed to respond to specific electrical conditions, making them versatile for different applications. Operators can adjust settings to protect against multiple fault types, ensuring the relay remains effective as system requirements and load profiles change.

-

Event Recording

Many advanced relays store detailed logs of fault events, enabling engineers to investigate the cause and location of failures. This information helps refine system protection strategies, prevent repeat issues, and improve maintenance planning for long-term operational reliability.

Best Practices for Using Protective Relays

Adhering to proven practices ensures that protective relays work seamlessly with switchgear and other protection devices, delivering fast, accurate fault isolation while preserving system stability.

Regular Testing

Scheduled functional tests confirm that relays are operating correctly and responding within the desired time frame. This helps detect calibration drift or faulty components early, reducing the risk of protection failures during live fault events and protecting downstream switching equipment.

Correct Coordination

Relay trip settings should be planned to ensure each protection device operates in the right sequence. This sequencing isolates faults efficiently and prevents disruption to unaffected parts of the system.

Periodic Calibration

As systems expand, upgrade, or experience changes in load profile, relay thresholds should be recalibrated. This preserves fault detection accuracy and ensures that relay response remains optimized for the connected switchgear’s capabilities and protection limits.

Cybersecurity Measures

For numerical relays connected to supervisory networks, strong authentication protocols, encryption, and firewall protection are essential. These measures prevent unauthorized access that could alter relay settings, safeguarding both system integrity and the reliability of switching operations.

Major Parameters in Protective Relay Settings

Correct relay settings are crucial for ensuring that protection systems work effectively. Major parameters like pickup current, time delays, and sensitivity must be optimized to balance fault detection speed with operational stability.

Pickup Current

It defines the current threshold that triggers the relay action. A correctly set pickup current ensures faults are cleared quickly while avoiding nuisance trips during normal load fluctuations.

Undersized settings can cause unnecessary interruptions; oversized settings can delay tripping, risking damage to connected switchgear and other assets.

Time Dial Setting

The time dial determines how long the relay waits after detecting a fault before issuing a trip command. Adjusting this delay helps balance fast fault clearance with operational stability, allowing momentary fluctuations to pass without interrupting service.

The setting should be chosen based on system load behavior, fault levels, and the protection sequence required for the specific application.

Reset Time

Reset time determines how quickly the relay reverts to its normal monitoring state after a trip. Short reset times improve readiness for subsequent faults, while longer resets can help prevent repeated operations from transient conditions that could cause mechanical wear on switching devices.

Sensitivity

It specifies how responsive the relay is to minor electrical anomalies. High sensitivity can catch early-stage faults before escalation, but in systems with frequent load changes, this must be balanced to prevent false tripping and unnecessary switch operations.

Challenges in Protective Relaying

Addressing these challenges is crucial to ensure relays function as intended and continue to safeguard power systems effectively.

-

Coordination Issues

Poor sequencing between protective devices can cause avoidable outages. When breakers or relays operate out of order, the result is wider system disruption, increased downtime, and potential equipment strain.

-

Maintenance Needs

Like any electrical device, protective relays require routine maintenance. Accumulated dust, mechanical wear, and vibrations from nearby equipment can reduce sensitivity or cause failures, making regular inspection essential for ensuring consistent and reliable relay performance.

-

Cybersecurity Risks

With the rise of digital and networked relays, cyber threats have become a concern. Unauthorized access can alter settings or disable protection, potentially leading to severe damage and safety hazards if faults occur without proper isolation.

Overcoming these challenges requires the right combination of technology, expertise, and reliable equipment. Partnering with a proven protection solutions provider ensures your relays and switchgear perform flawlessly during crucial operations.

Invest in the Right Protective Relay Today from LSElectric America Inc.

Electrical faults threaten asset integrity, disrupt operations, and create safety hazards. For industrial facilities, manufacturing plants, and high-voltage networks, a well-specified protective relay is a major component of system reliability and safety.

LS Electric America Inc. delivers protection solutions engineered for modern power systems, from precision overcurrent relays to advanced numerical relays for innovative grid applications. Each device provides rapid fault detection, selective isolation, and reliable system stability.

Our intelligent relays detect abnormal conditions early, preventing costly damage and avoiding unnecessary downtime:

- GMP – Electronic Motor Protection Relay

- DMPi – Intelligent Digital Motor Protection Relay

- IMP – Intelligent Motor Protection Relay

- MMP – Small Electronic Motor Protection Relay

Protect your operations with proven technology and industry expertise. Contact LSElectric America Inc. today to specify the right protective relay for your system and keep your power and productivity uninterrupted.